A threaded insert is a coil-shaped tool that can be inserted into a thread to improve the strength of the thread and repair the thread.

To use threaded inserts, you need internal thread to insert threaded inserts. That internal thread is called an insert screw. In order to machine insert screws, a special Tap Pilot hole drill screw gauge is required. The processing procedure is carried out in the following order:

|

|

| Insert screws are internal thread for inserting "threaded inserts". The outer diameter is large while the pitch remains the same compared to the original thread size. Requires special tools. It can also be processed with a thread mill. Pilot hole The diameter is different from ordinary screws. | A threaded insert is a coiled tool that reinforces the internal thread . It is also sometimes described as an insert, helisart, or sprue. Use the insertion tool to hold the part called the tongue and put it into the insert screw. The image is a product called "E-Cert". There is also a product called tangless insert, which does not have a tongue. |

(1) Drilling ( Pilot hole of insert screws)

Insert screws have a larger outer diameter than regular screws for inserting coils. The pitch is the same. The Pilot hole of an insert screw is different from a regular screw.

If you want to drill holes in aluminum or resin, we recommend the EX-SUS-GS high-speed drill for stainless steel.

(2) Tap machining (insert threads are machined with Tap for insert threads)

The Tap of the insert screw has the part name "HL". (A-SFT HL) thread mills can also be used to process insert threads. When calculating the cutting conditions for Tap , refer to the number () next to the thread size in the Pilot hole table for the Tap outer diameter.

(3) gauge Inspection (Inspection of insert screws) Screw gauge is used for insert screws. )

Gauge Inspection should be performed prior to insert insert using a thread gauge (HL-LG) dedicated to the thread accuracy of the drawing instructions.

Pass/fail: GO passes and the stopping side must enter more than 2 turns to pass

(4) Insert the insert (insert)

You will need three things: insert screws, insertion tools, and folding tools.

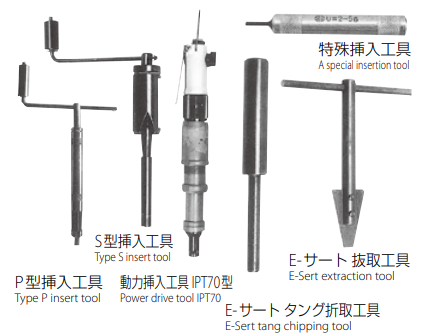

・ E-cert insertion tools, folding tools, and extraction tools

Threaded inserts can be selected according to the thread length. Choose from the effective thread length in the drawing instructions. Insertion tools will be required for each thread size. It is available in manual and electric versions. The motorized type can be equipped with a manual type of insertion tool at the tip for efficient work. A folding tool is also required to remove the tongue after insertion. Basically, it is not necessary, but if you want to remove it for some reason, you will need a special extraction tool.

Please note that the procedure may vary depending on the insert manufacturer.

How to insert a threaded insert

(1): Insert to the insert tool

(2): Insertion

(3): Remove the insertion tool

(4): Remove the tongue with the folding tool

Completion