When turning, I want to reduce the number of tools used to simplify tool management or consolidate the machining process, but what tools are suitable for me?

インデキサブルツール | オーエスジー

Showing 11-20 of 46 results

The 3D type material in Eco Cut is called "tungten alloy", but it is an alloy containing tungten and is not carbide.

It has a high modulus of elasticity and specific gravity, which improves vibration absorption performance during machining, contributing to high-precision machining, excellent surface quality and extended tool tool life .

References: Feat

Applications of 6 Corner shoulder milling Cutter Series PSTW

PSTW is suitable for machining with long overhangs that are prone to vibration and processing that requires higher efficiency.

In addition, PSE (rectangular single-sided 2 corners) is used for helical ramping processing.

For low-cut machining in small machining centers, P

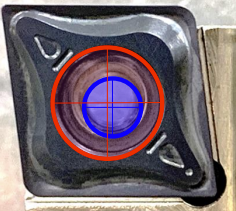

Actually, this is normal.

For indexable tools, it is common to have a structure with such a clamping allowance.

The OSG PHOENIX series indexable cutter is sold separately with a wrench.

The accuracy of the insert can be checked by the third alphabet of the insert's model number.

Refers to a shoulder milling cutter with a cutting edge angle of 90°.

It is a good rule of thumb up to around ~65HRC.

(FAQID:12975)

PFB-Q and PFB-Q-ST inserts can be undercut by selection.

All of them have a spherical effective cutting edge range of ~220°, which avoids the risk of interference with the wall during machining.

(FAQID:12976)