・ Minor diameter Turning

• External turning

・ End face turning

46 件中 1-10 件を表示

Multifunctional Cutter Series PMD

It is a multifunctional cutter of the Phoenix brand indexable type. With a single machine, continuous processing can be performed from the state of muku to plunge (hole processing) → horizontal milling . In addition to grooving and side processing, it can also be used for helical ramping, plunge proces

・Eco-Cut Classic cutting condition table

Cutting data during drilling

Cutting data during turning

・Eco Cut Mini

Cutting data of Eco Cut Mini

(FAQID:35)

Frequently Asked Questions of the Eco-Cut Series *You can see the Eco-Cut catalog here.

With Eco-Cut, you can perform processing work on flat surfaces, such as counterboring machining, with a single unit.

▼ References

Minor diameter High-efficiency machining

Example) When starting Pilot hole φ16 to minor diameter machining, the boring b

Processing is possible even without a dedicated adapter.

However, we recommend using an adapter for stable processing and repeatability of the cutting edge position.

References

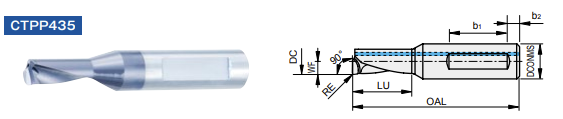

EcoCut Mini(ECM) small diameter Solid Type (Grade: CTPP435)

We do not recommend it.

Since the tool was originally intended for lathe machining, it cannot be used in tool rotation at a machining center.

(FAQID:39)

In the Eco Cut series, the Eco Cut Mini that can be made more small diameter is now available.

References: small diameter High Efficiency minor diameter Processing! Eco Cut Mini Series

EcoCut Mini(ECM)

Features of EcoCut Mini

Tool consolidation, machining time, an

Eco-Cut has a thick tool diameter with abundant rigidity and grooves with excellent chip discharge, which has the advantage of being less likely to cause problems in turning.

In particular, in minor diameter machining, conventional products such as boring bars have low tool rigidity, making it difficult to process with high efficiency.

In addition,