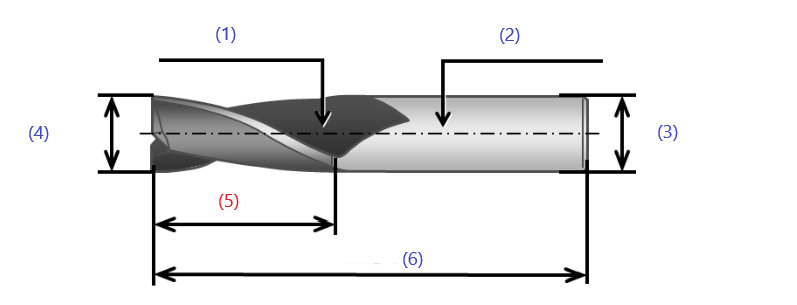

In general, slotting and drilling are difficult to discharge chips, and other processes that require a two-blade end mill to be used.

For machining that is easy to eject chips, such as side cutting, a four-blade ( multiple flutes ) end mill is used to in