However, it is also a tap that is prone to trouble where chips get entangled in the tap, or the tap

タップ | オーエスジー

88 件中 31-40 件を表示

However, it is also a tap that is prone to trouble where chips get entangled in the tap, or the tap

Forming tap is always cracked at the top of the thread pile during processing.

If the shape of the part is defective, the pilot hole diameter before forming tap machining is too large and the rise is insufficient.

Alternatively, it is possible that the pilot hole diameter is too small and is too raised (overrol

The cause of burrs in the forming tap can be the shape of the pilot hole, the lubricity of the cutting oil, and the cutting data. Please check the following points.

Pilot hole

・Finish of pilot hole diameter

・ Is the bend of the pilot hole and roundness bad?

・Conditions for pilot hole processing

After machining the forming tap , it is possible that the amount of raising is too large, and the height of the thread pile exceeds the target range.

If the chips are thin and short, it can be said that it is a good shape that is easy to discharge.

If the chips are thick and long, there is a risk of them getting caught in the tap, so you need to be careful.

In the case of spiral fluted tap , chips are discharged in the opposite direction to the direction of travel of the tap, so if the chips ar

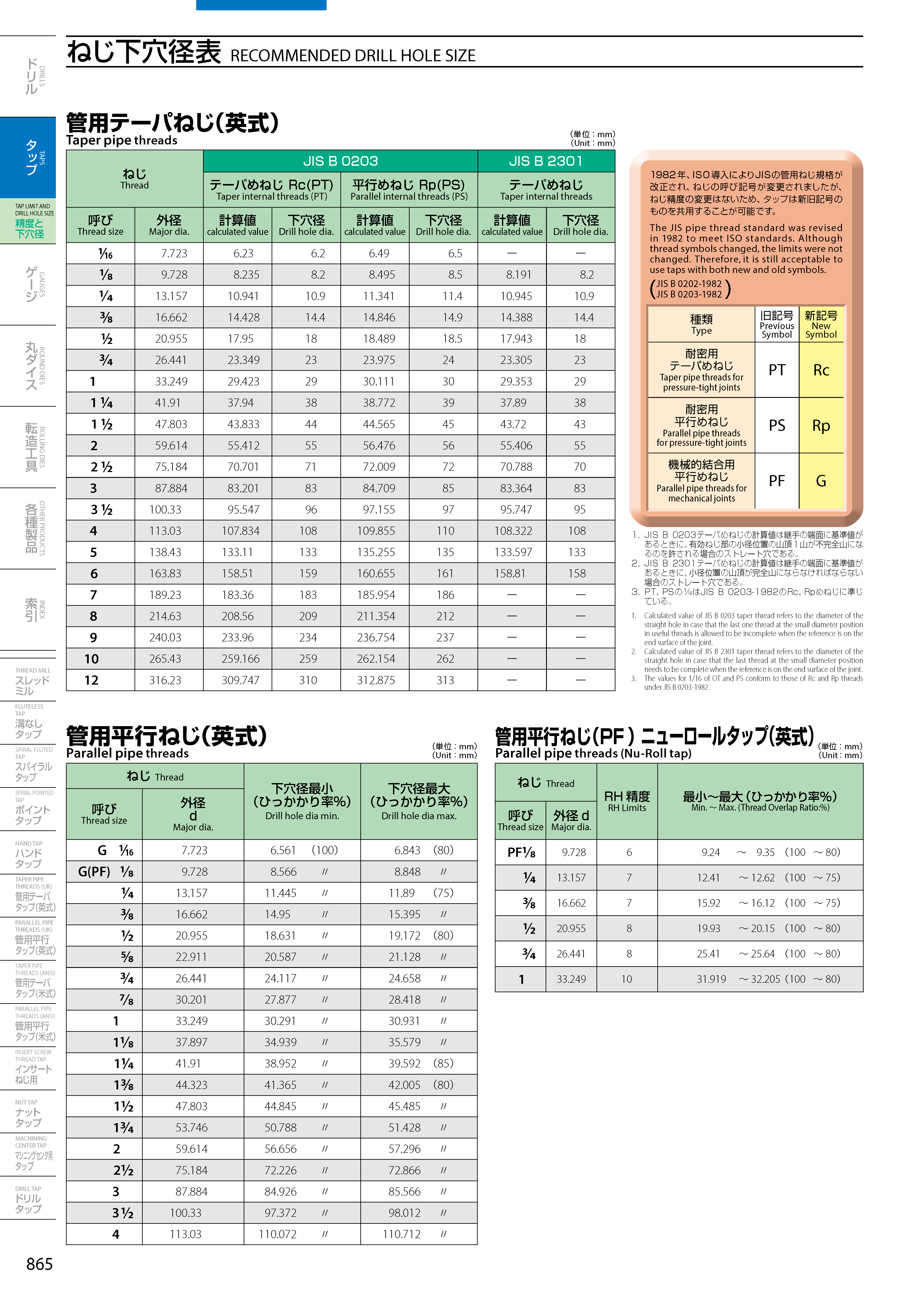

Pilot hole diameter of pipe screws PT, PS, Rc, Rp, PF, G

Unified Thread Cutting Tap Pilot Hole Diameter List

(ASNI) ASME B1.1

Metric Thread Pilot Hole Diameter of Grooveless Tap

New Roll Tap (NRT/XPF Series)

* Currently, the high roll tap (HRT series) is discontinued.

Are you using a synchronous feed mechanism and a float type tapper at the same time?

Even if the machine adjusts the pitch of one revolution, the Tupperware will float due to the load during machining, and the feed of the tap will be shifted.

When tapping with equipm