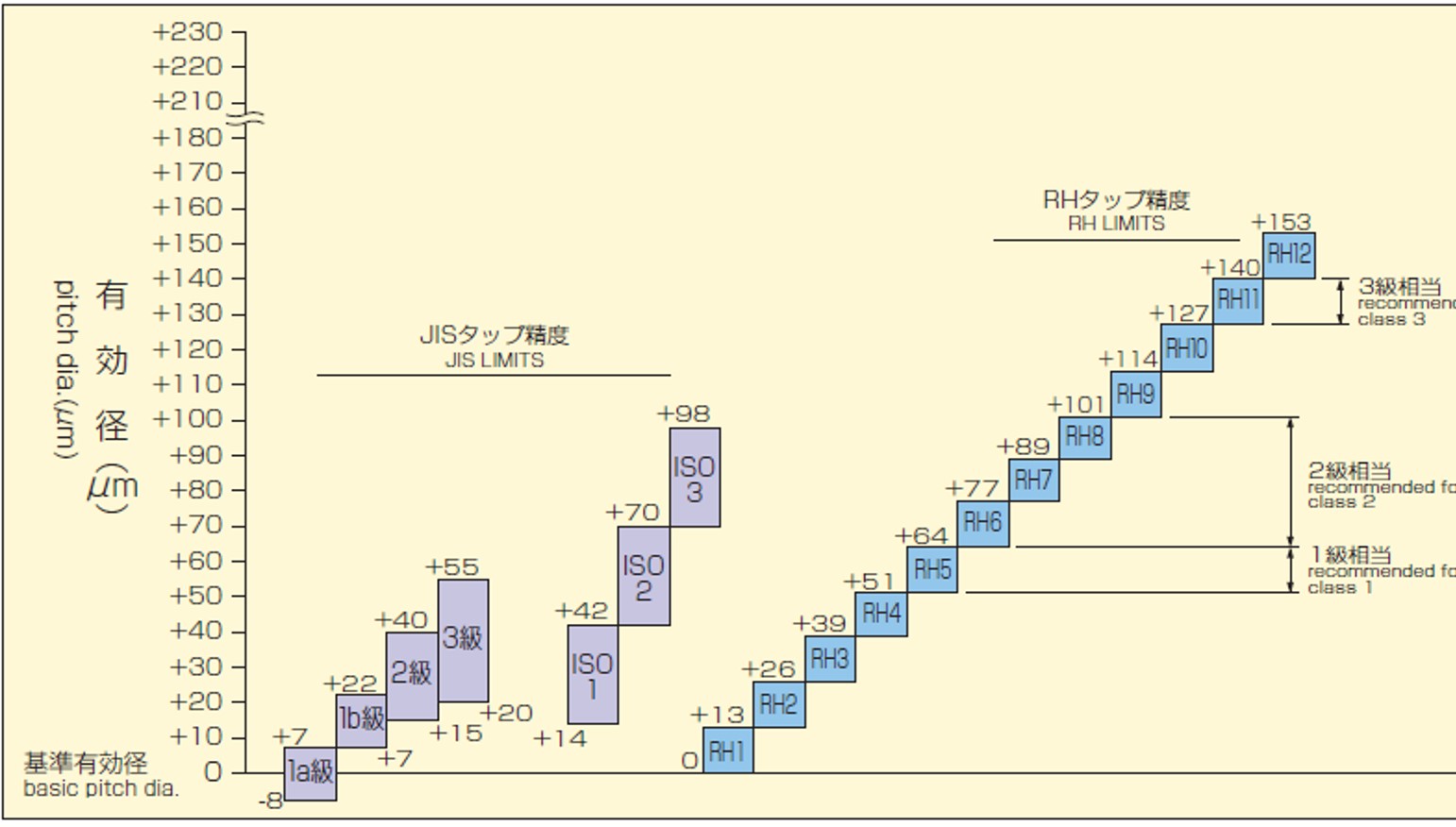

Internal thread Accuracy and tap accuracy ( forming tap :RH accuracy)

RH accuracy is the accuracy of forming tap .

The forming tap series (New Roll Tap, High Roll Tap) is designed to process internal thread by plastic deformation.

Strict pilot hole management is required, which is different from that of a cutting tap, and the accuracy of the tap is set strictly accordingly.

OSG uses a stepped accuracy with a tolerance of 12.7 μm.

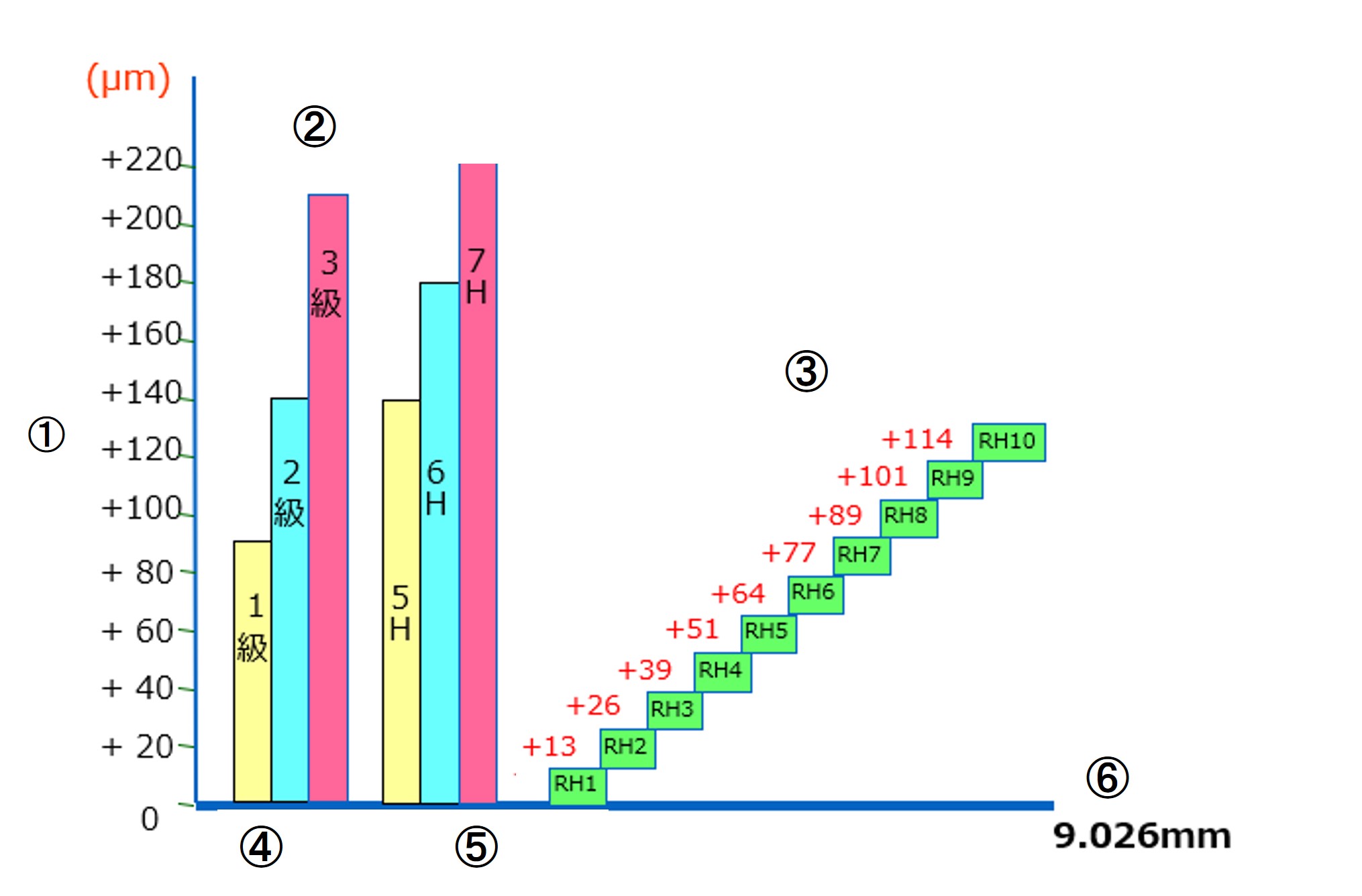

The table below shows the effective diameters of internal thread and taps.

|

|

(1) Effective diameter (2) internal thread accuracy (3) RH tap accuracy (4) Conventional JIS (5) Current JIS (6) Standard effective diameter |

When determining the accuracy of a internal thread , the effective diameter of the tap is one of the most important quality characteristics.

Normally, the standard level of tap accuracy is the grade 2 specified by the JIS, but tapped internal thread does not necessarily have the same accuracy as the grade of tapping.

This is due to the fact that the finished dimensions of the internal thread vary depending on the specifications of the tap, the material used, and the conditions of use.

For this reason, OSG has adopted a unique RH accuracy method that allows you to set the forming tap accuracy in stages and select it according to the work situation.

The tolerance of the effective diameter of the forming tap depends on the type of tap and the thread size.

You can check this from the catalog. There are two ways to express it, but both represent the same effective diameter of the tap.