| For removing broken taps |

| EX-H-DRL |

|

| Common name: Hard Drill |

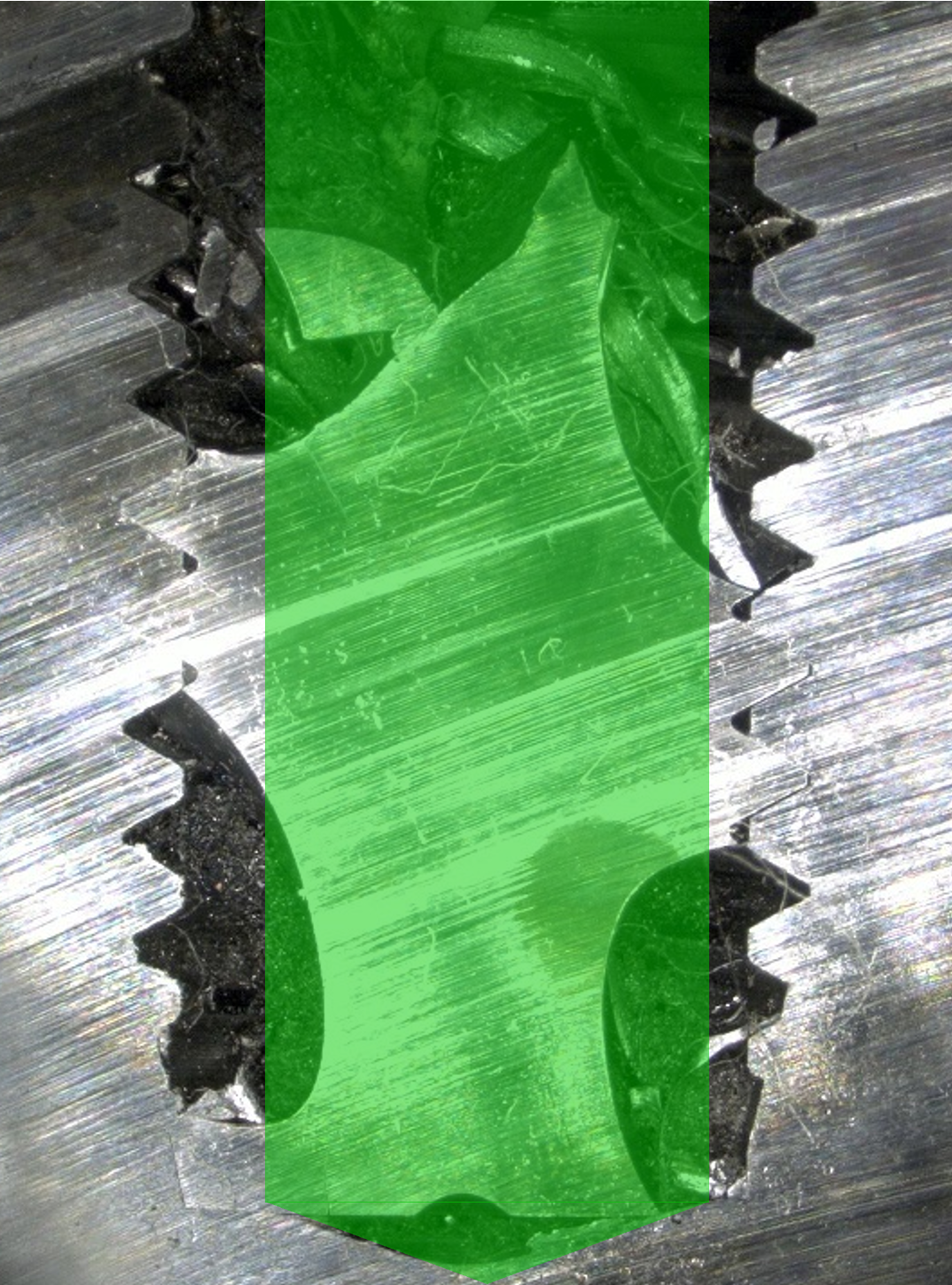

Broken tap section |

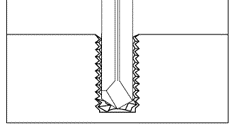

A hard drill is a drill that breaks the core of a broken tap (the green part in the photo).

After crushing the core, the threaded part that remained on the side can be removed.

Use the size of the hard drill that is adapted to the size of the broken tap.

How to use a drill for removing broken taps

| 【Retention~ centering 】 |

| (1) Hold the workpiece material and drill firmly |

|

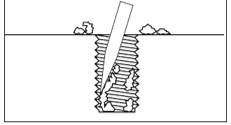

| Set the drill to the center of the tap. If the fracture surface is outside, flatten it with a grinder. |

| (2) centering (Centering) |

|

| Centering can be used with a drill larger than the tap adaptation size to prevent runout and process smoothly. |

| Centering After processing |

|

|

Centering Processing should be carried out without refueling. (Anti-slip) Hard drills should be sent little by little by hand. |

When using a hard drill, make sure that the workpiece is firmly fixed and centering to process the broken tap.

When centering , please adjust it by hand.

Centering At this time, the tool is easy to escape, so do not lubricate.

If you use a drill that is larger than the adapted size, it will be rigid and difficult to escape, so you can centering smoothly.

| [Hole processing ~ removal of residual parts] |

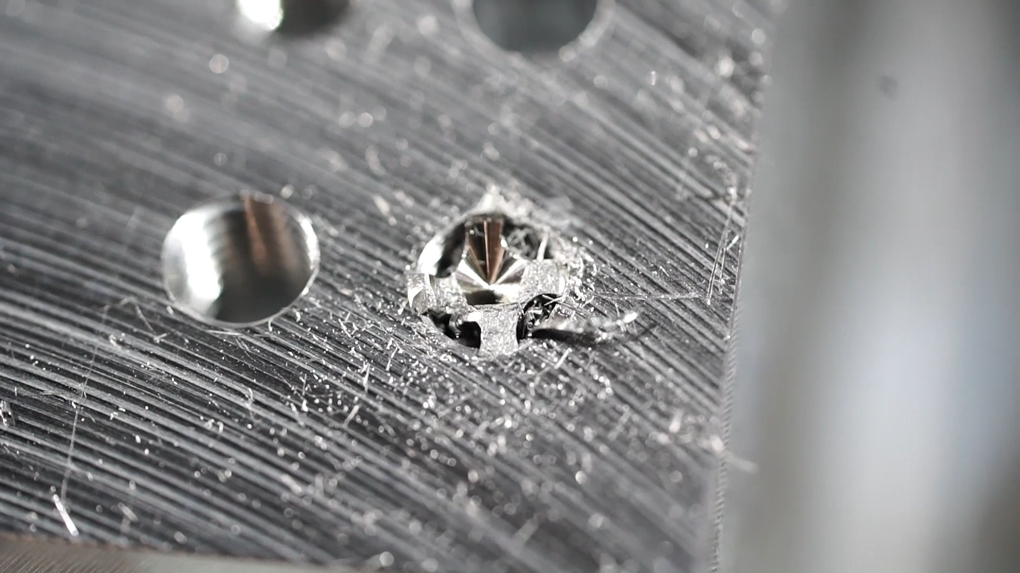

| (3) Hole processing |

|

| Please refer to the catalog and process with the drill of the appropriate size and conditions, while removing chips from time to time. Please be careful when penetrating. |

| (4) Tap residue and chip removal |

|

| After drilling, remove the remaining part of the tap with a scratching needle or tweezers. |

| Scene during hole processing |

|

| The cutting speed should be 20~25m/min. Refuel when drilling holes. The feed amount is 0.01~0.05mm/rev by hand. |

After centering , please process it by hand in the same way.

Once the core of the tap has been removed, remove the remaining screws of the tap with a needle or tweezers.

That's it.

【Notes】

You can use a cutting tap made of high-speed equipment. ( powder metallurgy HSS allowed)

Carbide taps forming tap not allowed

Not used for broken drill bolts

If the workpiece material is aluminum, there is a possibility of damaging the workpiece material.

If the screws are damaged, consider using a screw repair tool (screw insert).