Forming tap ( forming tap ) Machining Procedure

To process the forming tap , follow these steps:

Forming tap Machining Procedure (1) Pilot hole processing

Pilot hole drilling is performed.

* The pilot hole diameter is different from the cutting tap.

* Forming tap is greatly affected by the pilot hole diameter because the meat of the pilot hole is raised to make a thread.

* It is necessary to select the drill diameter that takes into account the tendency of expansion and contraction depending on the workpiece material.

* The diameter of the drill for the pilot hole should be determined by testing it with a drill several sizes larger.

Forming tap Machining Procedure (2) forming tap Machining

As with the cutting tap, it is processed with a movement of one rotation and one pitch.

The rotation speed is calculated from the cutting speed and the outer diameter of the screw in the catalog condition table (calculated as an outer diameter of 10 mm for M10).

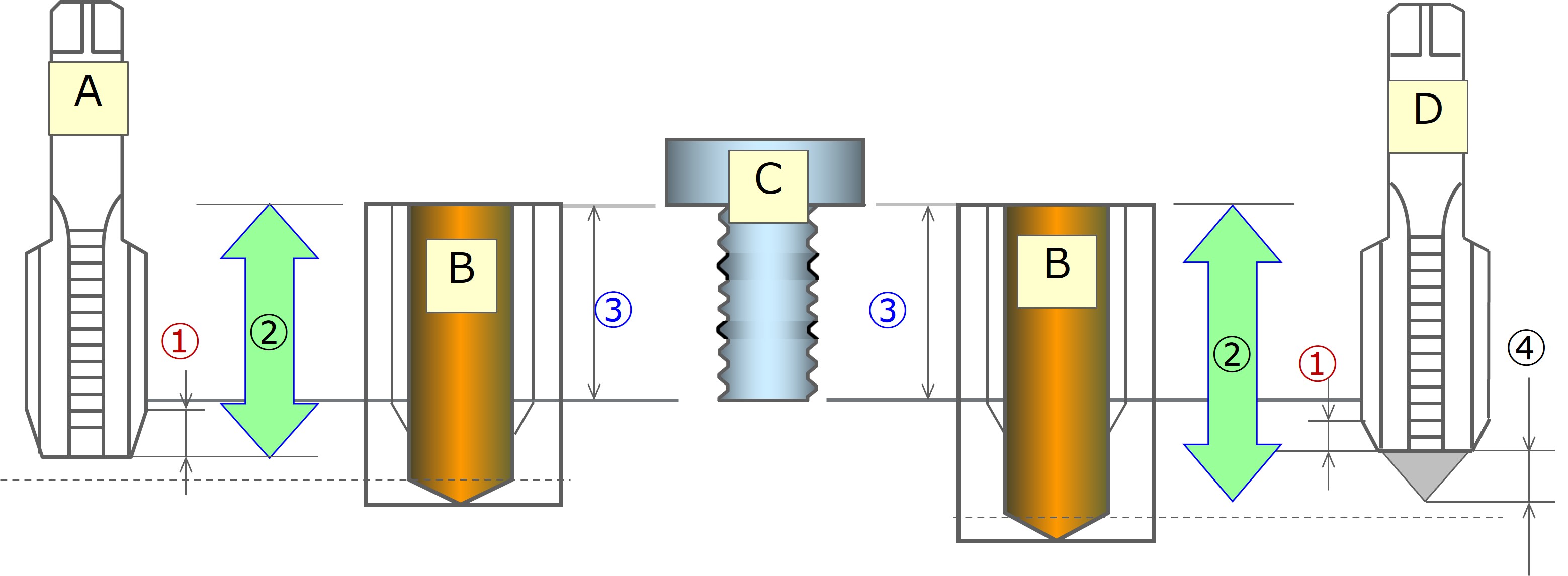

In the case of forming tap , even if the chamfer length 2P is written without external center , the center surface and the incomplete peak are left about 1P to improve insertion into the pilot hole.

Therefore, when machining with forming tap , please use it at a processing depth of 1.5P plus a margin to meet the effective thread length.

■ Tapping depth

Desired Thread Length (Effective Thread Length) + Bite Length (Incomplete Thread Length) + Margin 1.5 Pitch (for forming tap )

※ External center Yes, add its length as well.

|

|

A: No protruding center B: Pilot hole C: Bolt ( external thread ) D: Yes external center (1) chamfer (2) Tapping depth (3) Effective thread depth (4) external center Length |

Forming tap Machining Procedure (3) Gauge Inspection

Use the thread limit gauge with the thread accuracy indicated in the drawing.

For forming tap machining, it is necessary to measure the effective diameter and inner diameter of internal thread .

This is to confirm whether the inner diameter raised dimension is within the thread accuracy.

In that case, in addition to inspecting with a limit gauge for screws, please check the accuracy of the thread with a plug gauge for the inner diameter of the internal thread .