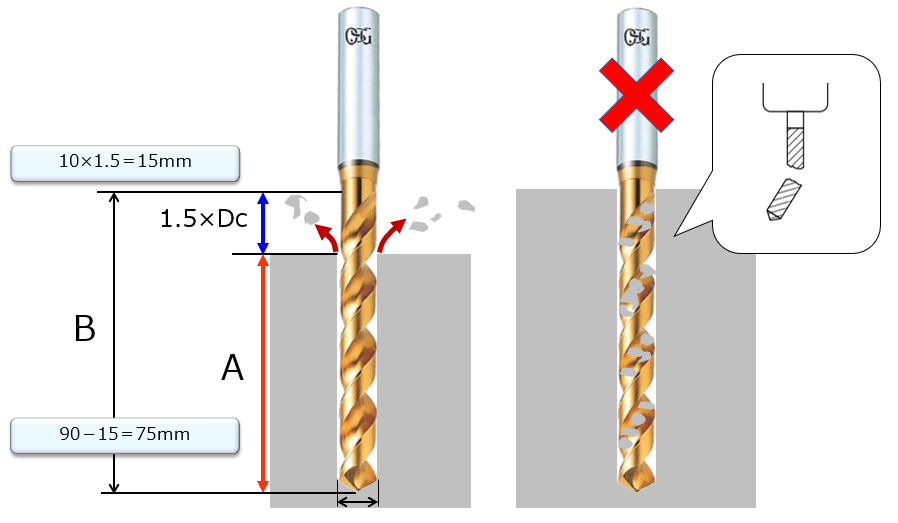

Since the drill digs while releasing chips, it is necessary to constantly drain chips from the trench to the outside. If you dig to the point where all the trenches are filled, you will not be able to drain the chips, and the chips will get stuck in the grooves and the drill will break. It is necessary to know in advance the depth of the hole that the drill can machine. The approximate depth at which a drill can drill is the flute length of the drill minus the drill diameter multiplied by 1.5. If a Φ10 drill is flute length 90 mm, the drill that can be drilled will be in the form of 90-15 = 75 mm. Let's check whether it can be machined with the drill for the hole depth indicated in the drawing.

Approximate hole depth that can be processed by the drill to be used (A)

(A)= (B) - (1.5 × Dc)

Example: Drill diameter φ10, flute length (B) Drill depth that can be machined with a drill of 90 mm

(A) = (B) - (1.5 × 10) = 90 - (1.5 × 10) = 75(mm)

When choosing a drill, choose a drill that has enough space to drain the chips for the depth of the hole you want to machine, flute length .

In addition, a drill is a tool that is used regrinding and many times.

Note that regrinding will also shorten the flute length .