Does the finish of the thread mill become smaller? What to do if the street gauge does not pass?

Since the thread mill is a cantilever tool, it may collapse or deflection due to the load during machining. Due to the deflection, the finish of the screw may be small, and the screw gauge on the street side may not pass.

In order to reduce the load during machining and aim to pass the screw gauge, the following measures are effective.

・ Adjustment of cutting data

Adjust the rotation speed and feed speed according to the condition range of the tool to be used. In particular, the feed rate needs to be corrected, so we recommend that you adjust it in the program creation application "ThreadPro" and create the program again.

AT-1, Insert Changeable Type Thread Mill Cutting Data Table

AT-2 Series Cutting Data Table

・ Increase the number of passes

By adjusting the allowance, we aim to suppress the fall.

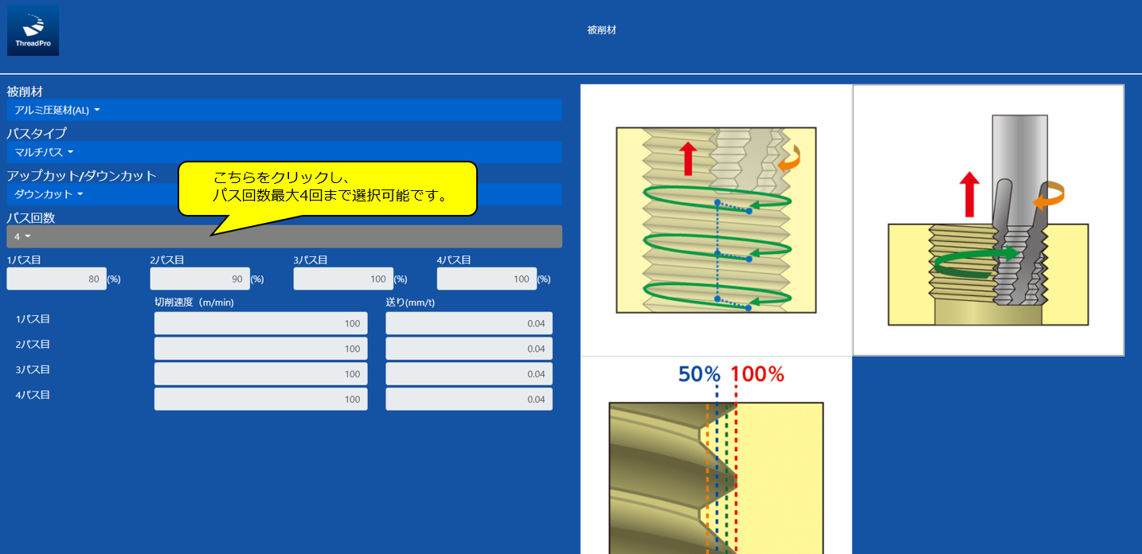

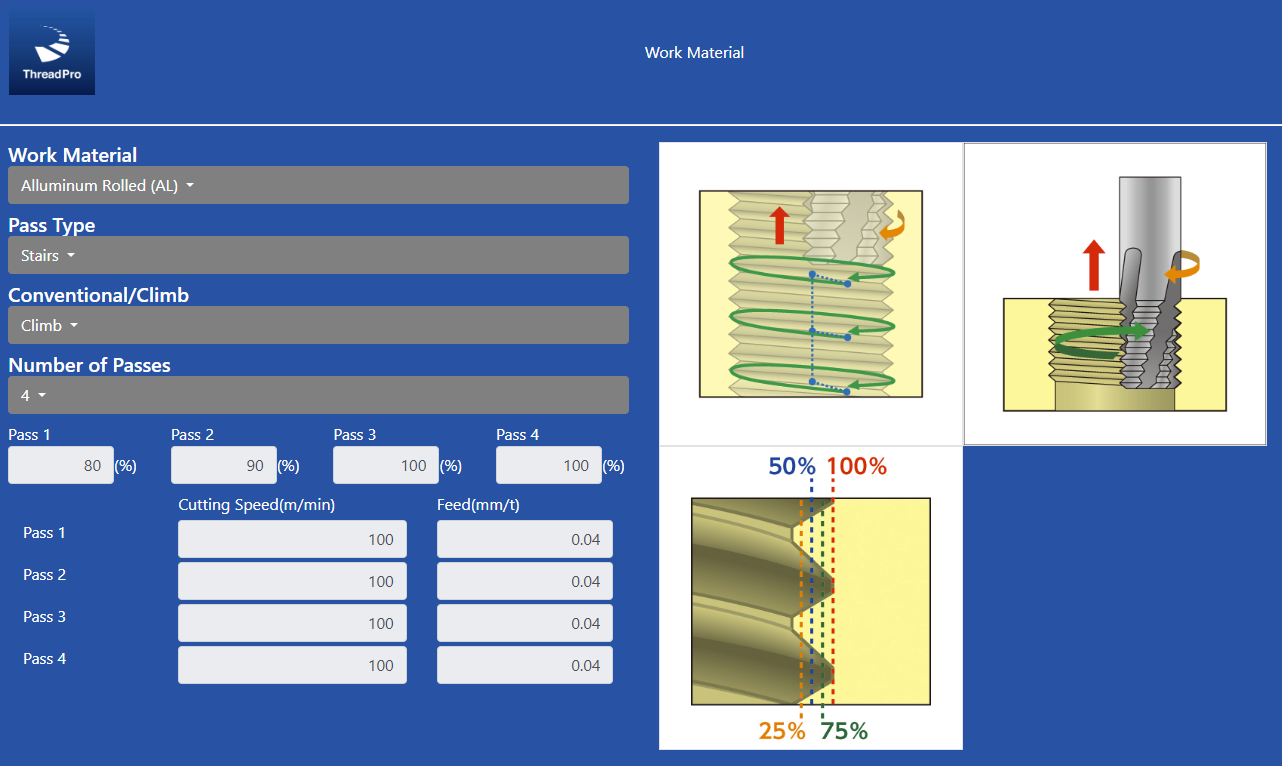

With the NC program creation application "ThreadPro" for thread mills, it is possible to create a program with an increased number of passes.

You can specify the amount of cuts to be made as a percentage for each number of passes.

By doing 100% multiple times, you can set a zero cut.

Japanese version

You can select up to 4 passes in English.

(FAQID:871)