What are additive manufacturing end mills AM-EBT AND AM-CRE?

This is a tool for milling the surface layer in additive manufacturing (= metal additive manufacturing method that is performed while adding materials like a 3D printer).

Available in AM-EBT (ball type) and AM-CRE (radius type), it is equipped with a negative blade type and unique specifications that take chip ejection and regrinding into consideration, and can stably respond to environments where uneven replacement is likely to occur due to high hardness and unevenness.

It is also effective for processing overlay and welds.

| AM-EBT (Ball Type), | AM-CRE (Radius Type, 6 Blades/8 Blades) | ||

|---|---|---|---|

Example: R6 |

Example: φ10×R2 |

||

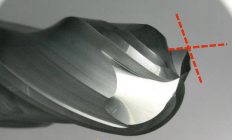

• Ball (AM-EBT) or corner radius (AM-CRE) outer groove is negative-shaped

→ AM (metal lamination) Compatible with hard parts of the surface layer and fluctuations in the allowance!

• Extra chip pockets

→ Compatible with changes in AM replacement load and improved discharge of increased chips!

• multiple flutes for long life and high efficiency using a 5-axis machine (AM-CRE)

Supports high efficiency such as → blade processing!

• Ultra-heat-resistant and high-toughness DUROLEY coating

(FAQID:8227)