What is Thread Mill AT-2 with end cutting edge for High Hardness Steel?

It is a thread mill with end cutting edge for high-hardness steel.

| High Hardness Drill for Pilot hole High | Hardness Tap |

|---|---|

|

|

| Approximate cutting speed: 20~30m/min Cutting oil: Water-soluble cutting oil |

Approximate cutting speed: 1~3m/min Cutting oil: insoluble cutting oil |

Depending on the machine specifications, there is a range of conditions that we are not good at.

If the workpiece is removed, even a slight shift in the center will cause instability during machining.

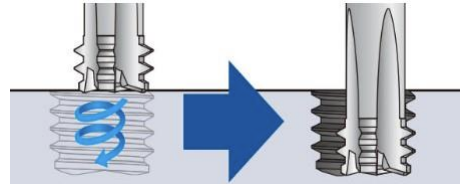

New proposal: Simultaneous processing of helical drilling + threading

Thread Mill with end cutting edge for High Hardness Steel AT-2

A thread mill is a tool that uses the helical machining of a machining center to perform thread machining.

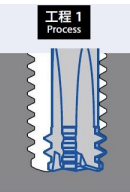

Depending on the type of thread mill, Pilot hole is drilled and threaded on the Pilot hole , but this AT-2 achieves stable processing with less risk even in high-hardness steel, which is difficult to process, by simultaneously drilling + threading.

| Conventional: Pilot hole Drill + Tap | AT-2 | |

|---|---|---|

|

|

End of → |

| ・Risk of sudden breakage is unavoidable ・Requires 2 tools |

・Reduce the risk of sudden breakage by subdividing chips ・ One tool |

|

There is no need to prepare a separate machining environment that should be prepared, such as a machine that is good at the recommended condition range and a suitable cutting oil.

All you need to do is prepare the range of conditions in the AT-2 condition table and the cutting oil (or air blow ).

・ Since Pilot hole and thread processing are processed at the same time, there is no risk of instability due to phase shift, such as removing the workpiece.

・Since the chips are also finely divided, the risk of sudden breakage can be suppressed.

・Tools can also be consolidated into one.

|

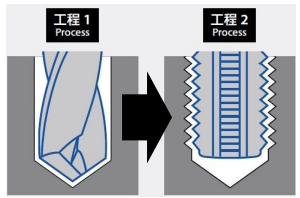

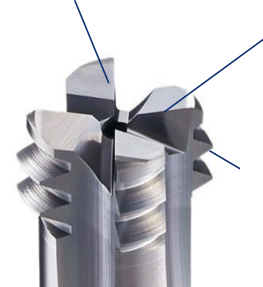

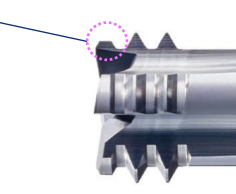

Left Blade Left-hand blade that can process Pilot hole at the same time at the climb cut , which is advantageous for tool tool life * Please use with spindle reversal (left rotation) |

|

|

With end cutting edge Direct screwing without Pilot hole |

|

Special blade type PAT. in Japan Proprietary specifications suppress tool deflection even in high-load environments, and stabilize accuracy |

|

|

Mt. Araba Dividing the allowance during thread machining into stages and distributing the load |

|

ThreadPro

・ You can use it without downloading. (Internet browsing app required)

It can be used from smartphones and tablet PCs.

- Display of RPRG (RPRG: Reference value of tool diameter radius correction value)

・Helisart compatible

- Compatible with the addition of the latest tools, etc.

- Multilingual support (12 countries)

・ Various types of NC compatible (8 types)

You can reduce the time and effort required to create programs.

Since it can be used before the tool is purchased, it can be used for tool selection and machining time.

(FAQID:7843)