The "tolerance" is the difference between the maximum and minimum values of a given dimension.

"Tolerance" is the difference between the limit value allowed for the reference dimension.

The larger one is referred to as the "upper tolerance" and the smaller one is referred to as the "lower tolerance" relative to the reference dimension.

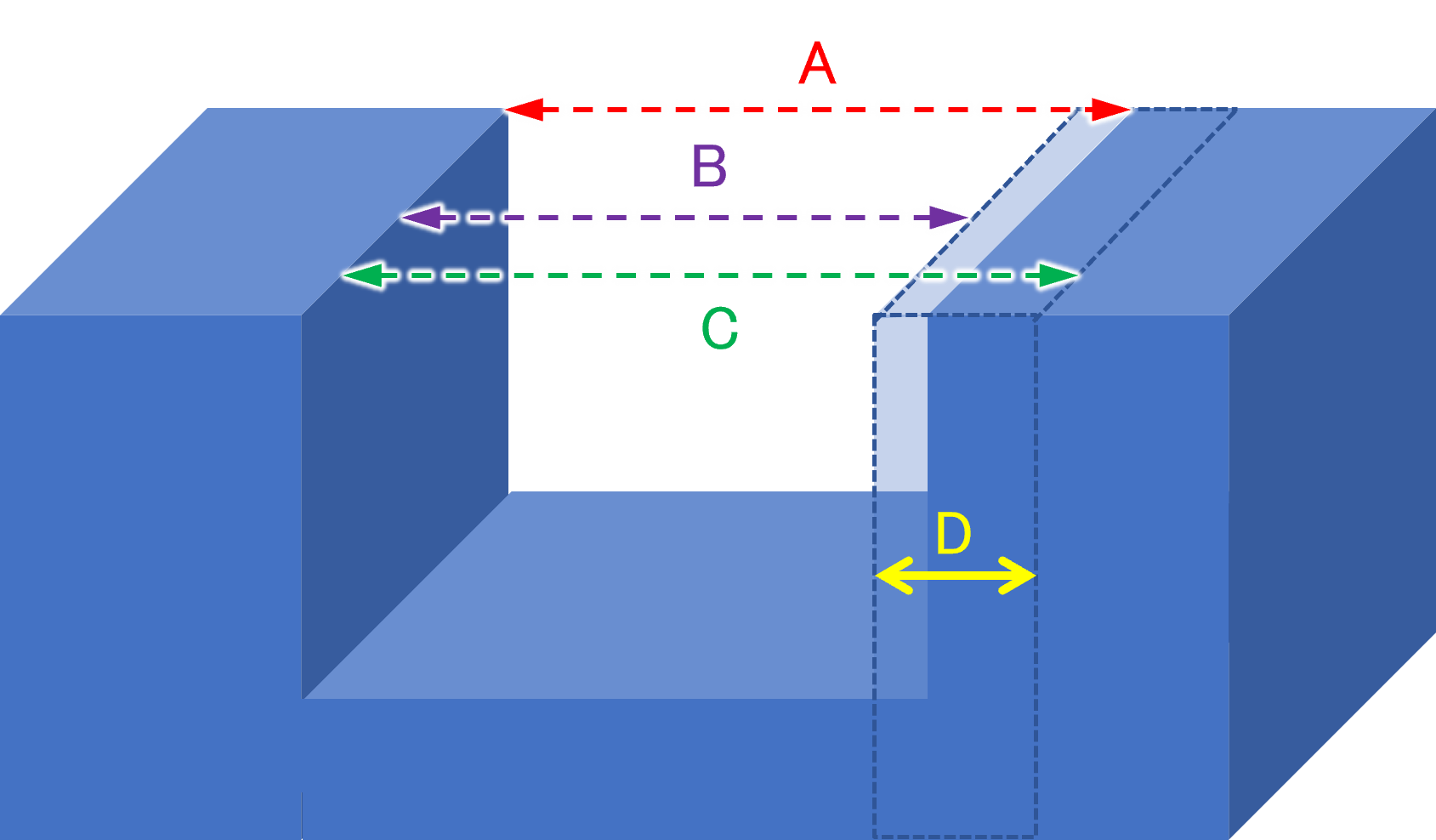

[Example of drawing instructions]

| < drawing > 10.0 -1.0/2.0 |

|

| A: Standard dimension 10mm B: Lower tolerance -1.0mm (9.0mm is also OK) C: Upper tolerance +2.0mm (12.0mm is OK) D: Tolerance 12.0-9.0=3.0mm |

For a groove width with a standard dimension of 10.0 mm...

When the upper tolerance is +2.0mm and the lower tolerance is -1.0mm, the minimum allowable groove width is

10.0mm - 1.0mm = 9.0mm The maximum allowable groove width is 10.0mm + 2.0mm = 12.0mm.

The tolerance is calculated to be 12.0mm-9.0mm=3.0mm. In drawing notation, it is expressed as 10.0 -1.0 / 2.0.