For external coolant supply

With a vertical processing machine, there is no step up to 3D hole depth. If you exceed 3D, you can use 1D~2D steps as a guide. (D: Drill diameter)

If you are using a horizontal processing machine, if the drilling hole depth exceeds 2D, you can use 0.5D~1D steps as a guide.

However, if the drill φ3 or less, the non-step is up to 1D, regardless of whether it is vertical or horizontal. After that, please consider 0.5D steps.

Be careful not to step too finely, as this can cause premature wear and work hardening of the drill margins.

For internal coolant supply

In the case of carbide drills with oil holes, carbide drills with ~D are basically recommended to be non-step up to that depth.

However, due to the characteristics of the workpiece material and insufficient coolant pressure (2 MPa or more), processing heat and chip volume may occur.

If there is a problem with the actual processing, please consider cooling and discharge by step processing (G83).

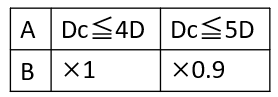

For high-speed drills with oil holes such as EX-HO-GDR, if the drilling hole depth exceeds 4D, use a vertical or horizontal machine, and perform steps of about 1~2D for both and adjust the cutting speed as shown in the table below.

(A) Hole depth (B) Cutting speed suppression factor