What is point angle Effects of Drill point angle

Point angle is the angle of the tip of the drill.

In general, 118° is the standard for high-speed steel, and 140° is standard for carbide steel.

The smaller the point angle , the smaller the vertical resistance (thrust resistance), but the tip is chipping easier and the chips are thinner. As the point angle increases, the chips will be thicker, shorter, and better, but the thrust resistance will be larger.

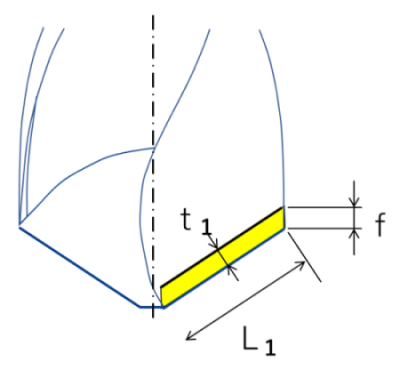

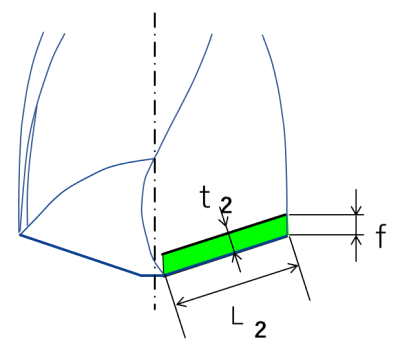

Point angle and net depth of cut

| Point angle Small | Point angle Large |

|

|

| If the point angle is small (sharp angle), the chips will become thinner and tend to remain extended. | If the point angle is large (obtuse angle), the chips are thick, easy to divide, and have high discharge. |

|

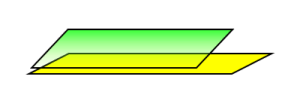

L: Cut flute length ⇒ L1 > L2 t: Chip thickness ⇒ t1 < t2 f: Amount of feed per revolution The larger the chip shape, the better the point angle

|

|

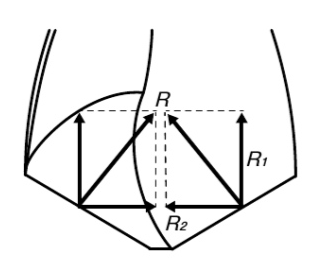

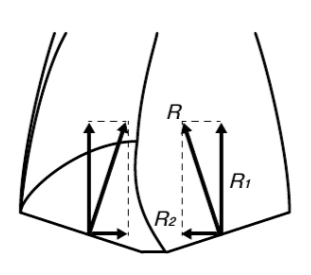

References: point angle and Thrust Resistance

| Point angle Small | Point angle Large |

|

|

|

Point angle is easier to enter the smaller one (sharp angle) R: Cutting force R1: Thrust resistance: The force of resistance applied in the opposite direction to the direction of travel R2: Rotational force |

|

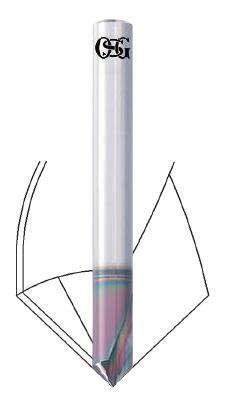

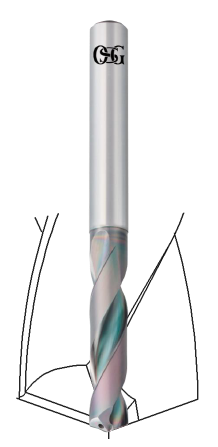

▽ Point angle

| Small point angle | General point angle | Big point angle |

|

|

|

| Example: 90° | Example: 118° | Example: 140° |