Even though the hole position is centered, the hole position becomes unstable. What can be done to improve the accuracy of the hole position?

When the drill starts to hit the workpiece from the shoulder, it is not possible to get the hole position properly.

Defect examples

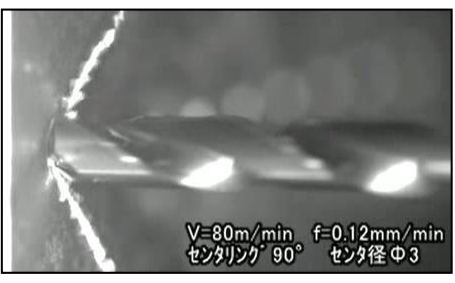

Point angle 90° starting drill for chamfering, centering larger than the diameter of the drill

It is then drilled at a 120° point angle

In this case, the 120° drill begins to hit from the shoulder, and the hole position becomes unstable.

How to improve

Chamfering and centering should be processed separately. For centering, use an spotting drill with the same point angle as the drill or at an angle greater than the point angle of the drill. In particular, it is important to consider the point angle of short and long drills for guide holes in deep hole drilling.

References: Centering Tips

| (A) Reducing the processing diameter without changing the angle | (B) Expand the angle to more than point angle drill |

| Centering angle: 90° Centering diameter: φ3 |

Centering angle: 160° Centering diameter: φ10 |

|

|