What are the causes and countermeasures for hole enlargement in drilling?

The enlargement of the hole is caused by the runout and vibration of the tool during machining.

In addition, the runout of the outer circumference during installation affects the hole diameter and hole position accuracy.

Even with a high-rigidity and high-precision drill such as the EX-GDR, if the drill is used with a large runout during installation, the hole enlargement and hole position accuracy will decrease. This tendency is even greater for drills with low stiffness.

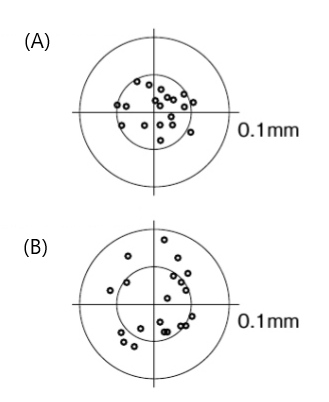

Effects of runout during installation

(A) Runout during installation = 0.034mm

(B) Runout during installation = 0.112mm

Countermeasure

・Suppresses runout when installing the drill.

- Review the amount of feed per revolution of the drill. (Drill outer diameter× 0.02 approx.)

・Consider changing the tool base material from high-speed to carbide. ( base material is hard and hard to shake)

If the hole enlarges after drilling regrinding

Check the lip height (difference in height of the drill blade). (0.03mm or less recommended)

・Check if the chisel point is eccentric. (Confirmation of thinning)