Cutting data of long blades

The EDL cutting data table is not listed in the catalog, but the feed and rotation are adjusted according to the amount of protrusion based on the cutting data of the general end mill EDS.

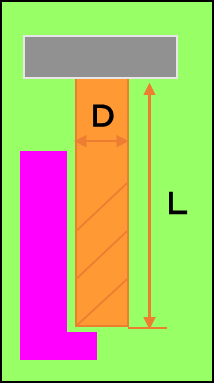

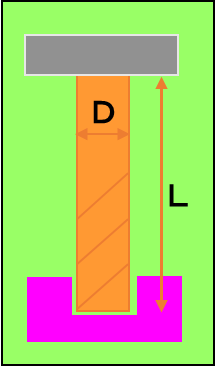

References: Overhang and cutting data

| L/D | kind | Cutting speed | Amount of feed per blade | Feed speed (work) | Depth of cut |  |

| ~3.5 | short | 100 | 100 | 100 | 1.5D×0.1D | |

| 4~6 | Long | 40 | 70 | 30 | 3.5D×0.01D | |

| 6~8 | EX Long | 20 | 40 | 10 | 3.5D×0.01D | |

| 10~ | Super EX Long | 10 | 20 | 2 | 3.5D×0.01D (0.005D) |

| L/D | kind | Cutting speed | Amount of feed per blade | Feed speed (work) | Depth of cut |  |

| ~3.5 | short | 100 | 100 | 100 | 0.5D | |

| 4~6 | Long | 40 | 80 | 30 | 0.25D | |

| 6~8 | EX Long | (10) | (40) | (4) | (0.1D) | |

| 10~ | Super EX Long | - | - | - | - |

The figures in parentheses are for reference only. Before use, check the cutting status by trial cutting and then determine the cutting conditions.