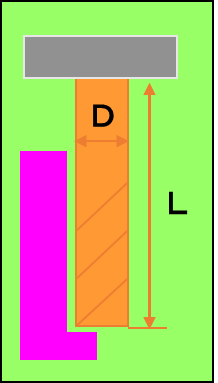

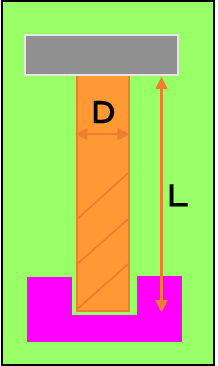

How much cutting data should be adjusted depending on the flute length and overhang length of the end mill?

The longer the amount of protrusion relative to the diameter of the tool, the more vibration and deflection will occur during machining. By lowering the conditions, it is possible to reduce the force that causes vibration and deflection, so such phenomena can be reduced.

Please adjust the table below according to the L/D value, which is the ratio of flute length and overhang length . It shows the suppression ratio of the cutting data to the catalog conditions of the short blade type. The cutting situation varies depending on the processing environment and the workpiece, so please consider it as a reference value.

▽ Approximate conditions due to differences in flute length [Ratio: %]

| L/D | Kind | Cutting speed | Amount of feed per blade | Feed speed (work) | Depth of cut |  |

| ~3.5 | Short | 100 | 100 | 100 | 1.5D×0.1D | |

| 4~6 | Long | 40 | 70 | 30 | 3.5D×0.01D | |

| 6~8 | EX Long | 20 | 40 | 10 | 3.5D×0.01D | |

| 10~ | Super EX Long | 10 | 20 | 2 | 3.5D×0.01D (0.005D) |

| L/D | Kind | Cutting speed | Amount of feed per blade | Feed speed (work) | Depth of cut |  |

| ~3.5 | Short | 100 | 100 | 100 | 0.5D | |

| 4~6 | Long | 40 | 80 | 30 | 0.25D | |

| 6~8 | EX Long | (10) | (40) | (4) | (0.1D) | |

| 10~ | Super EX Long | - | - | - | - |

The figures in parentheses are for reference only. Before use, check the cutting status by trial cutting and then determine the cutting conditions.

Please consider that high-rigidity tools for vertical wall processing may be able to perform high-precision machining with higher efficiency than in the table below.

・ Vertical wall compatible carbide anti-vibration type end mill AE-VMFE