How to machine right-angle shapes with an end mill? Sharp Corner Edge Gaze

In order to machine a right-angle shape with an end mill, the tool side that processes it must also have a right-angle shape when rotated. The shape of the tool side is called the sharp corner edge.

The corners of the high-end mill are all sharp corner edge specifications except for the long type, luffing type, and high-helix type. * CC-EMS, EDS, etc. are sharp corner edge specifications.

Due to the high hardness of the base material and the ease of chipping , many carbide end mills are designed to remove the corners of the cutting edge to prevent blade chipping . The specification to take the corner of the cutting edge is called "chanfa" or "gash application".

Compared to those with right angles, the end mill with the gash specification is more efficient and tool life long.

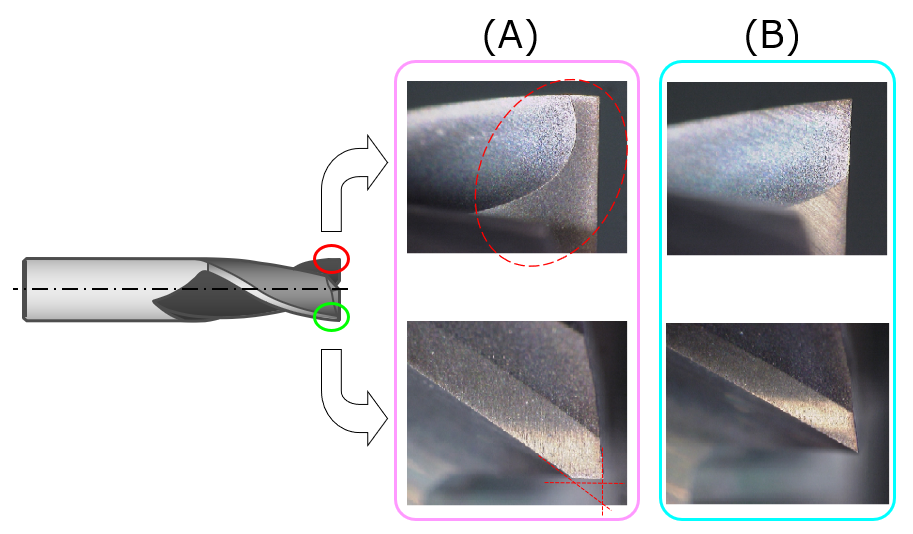

・ Shape of the cutting edge of the end mill

(A): Gash (B): Sharp corner edge specification

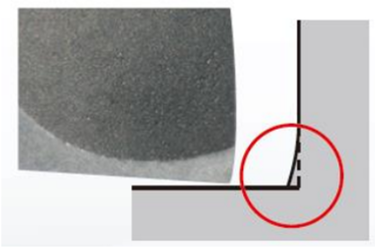

With an end mill with a gash applied specification, it is not possible to make the workpiece into a right-angle shape.

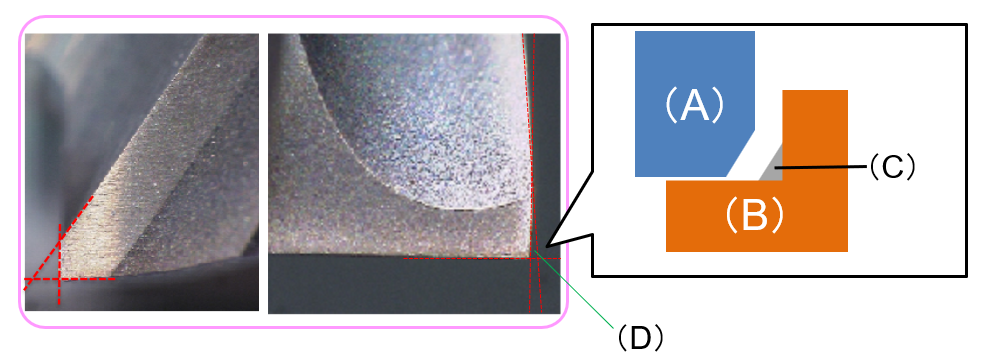

(A): End mill (B): Workpiece (C): Rest (D): Part reduced by gashing

The problem for processors who want to produce a common right-angle shape is that it is difficult to balance the following.

・ Gash applied end mills do not produce right angles.

・ chipping is likely to occur in an end mill that is not gashed.

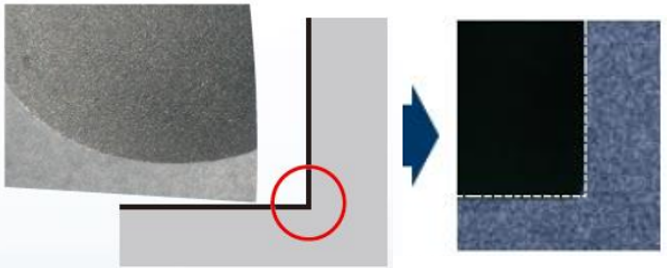

If you want to process right-angle shapes with high efficiency, we recommend the right angle type of the AE-VM series of carbide end mills. Right angle means right angle. The right-angle type has a shape that does not change the diameter of the end mill tip due to a special gash, and it is possible to achieve a right-angle shape on a wide range of workpiece materials while suppressing chipping even under high-efficiency conditions. (-RA is written at the end of the tool diameter)

| Square Type |

Right Angle Type |

|

Right-angle corners with no shavings

|