Tool selection based on HRC hardness

When the material to be machined is not listed in the corresponding material column of the catalog, or when the properties have changed due to tempering, etc., the hardness of the workpiece material is one guideline for tool selection.

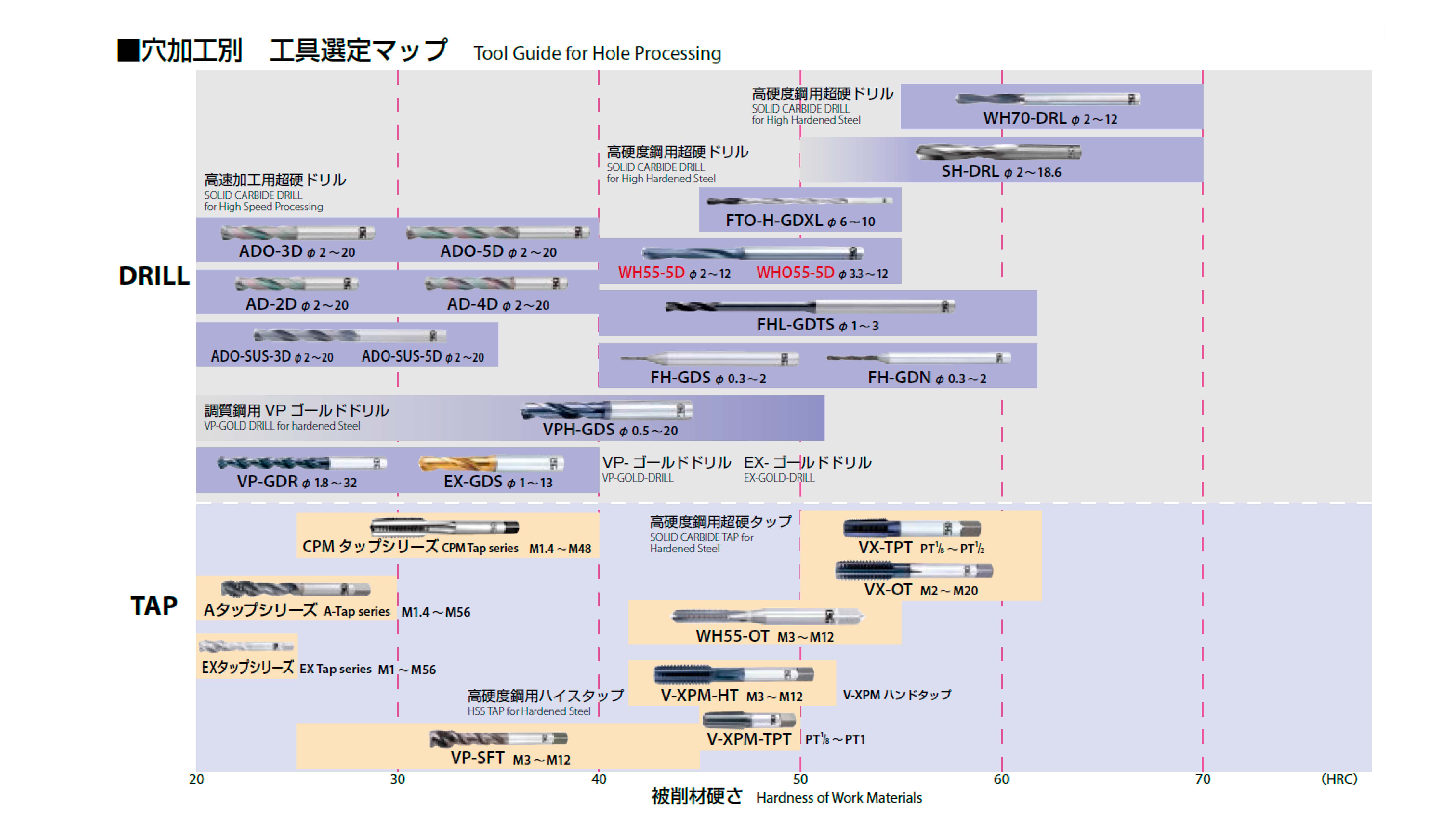

■ Selection table of drills and taps by material hardness

This applies not only to drills and taps, but also to end mills.

Please refer to the corresponding guideline for each HRC hardness in the quenched steel section of the corresponding material column.

Application-specific tools such as SUS and deep hole tools have specifications according to the material, such as weld resistance and sharpness of the cutting edge, in addition to hardness. In some cases, tools for materials with similar properties may be suitable for the material to be machined.

Of course, unlike those made exclusively for use, it is necessary to adjust the cutting conditions, cutting oil, and other defects.

Since standard products can be repurposed, there is an advantage that the range of correspondence is expanded.

As an example, the sharp sharpness and coating of high-speed drills for SUS can also be used for copper alloys (20HRC or less).