What is Upper Thirds Tap?

At the request of customers such as "tight when external thread is inserted", "plating on internal thread ", "strain countermeasures by heat treatment after internal thread processing", etc.

Larger screws may be required. In that case, you will use a so-called "over-size" tap that is larger than the standard.

* In the notation in the JIS Handbook, it is not "oversized" but "oversized".

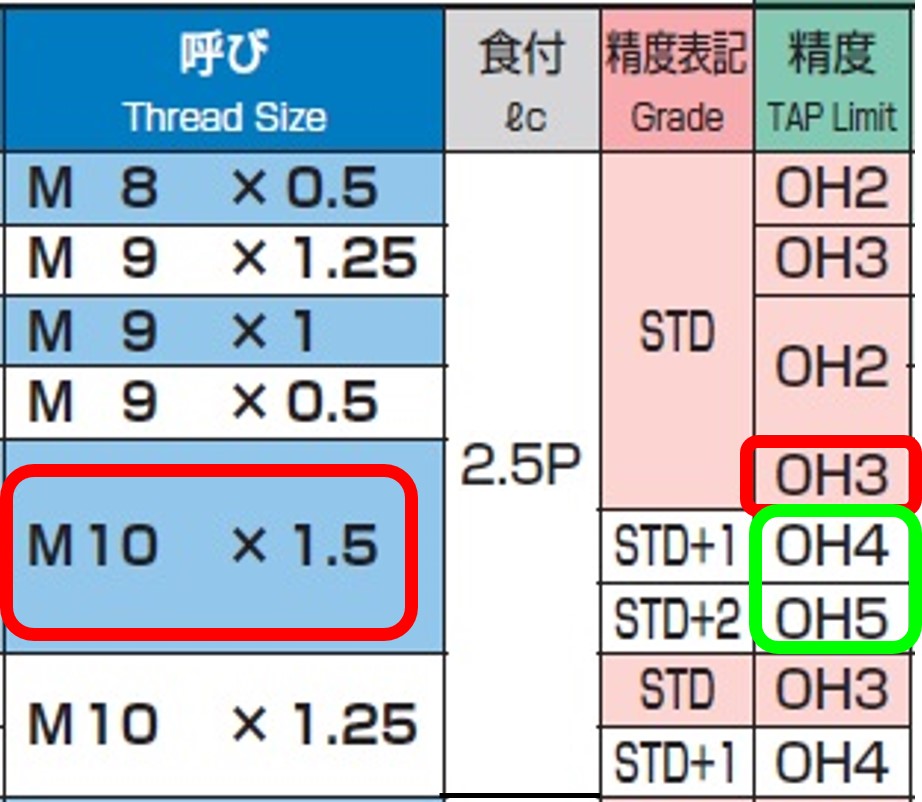

In the accuracy notation of taps in the catalog, the "STD" identified in pink means standard, and is the recommended accuracy of taps that are equivalent to Grade 2 internal thread .

In the "Accuracy notation" of the tap in the following document, STD+1 and STD+2 are "over-size" taps with a larger effective diameter than the standard "STD".

The STD is set by the size and type of tap.

e.g. EX-SFT M10X1.5

The accuracy field "STD" is the recommended tap accuracy of the 2nd grade internal thread equivalent, and if the number is higher than that, it is called "oversized".

It will be +0.02mm over 1 rank.

*STD stands for STANDARD. There is always one for each size of every tap. |

|

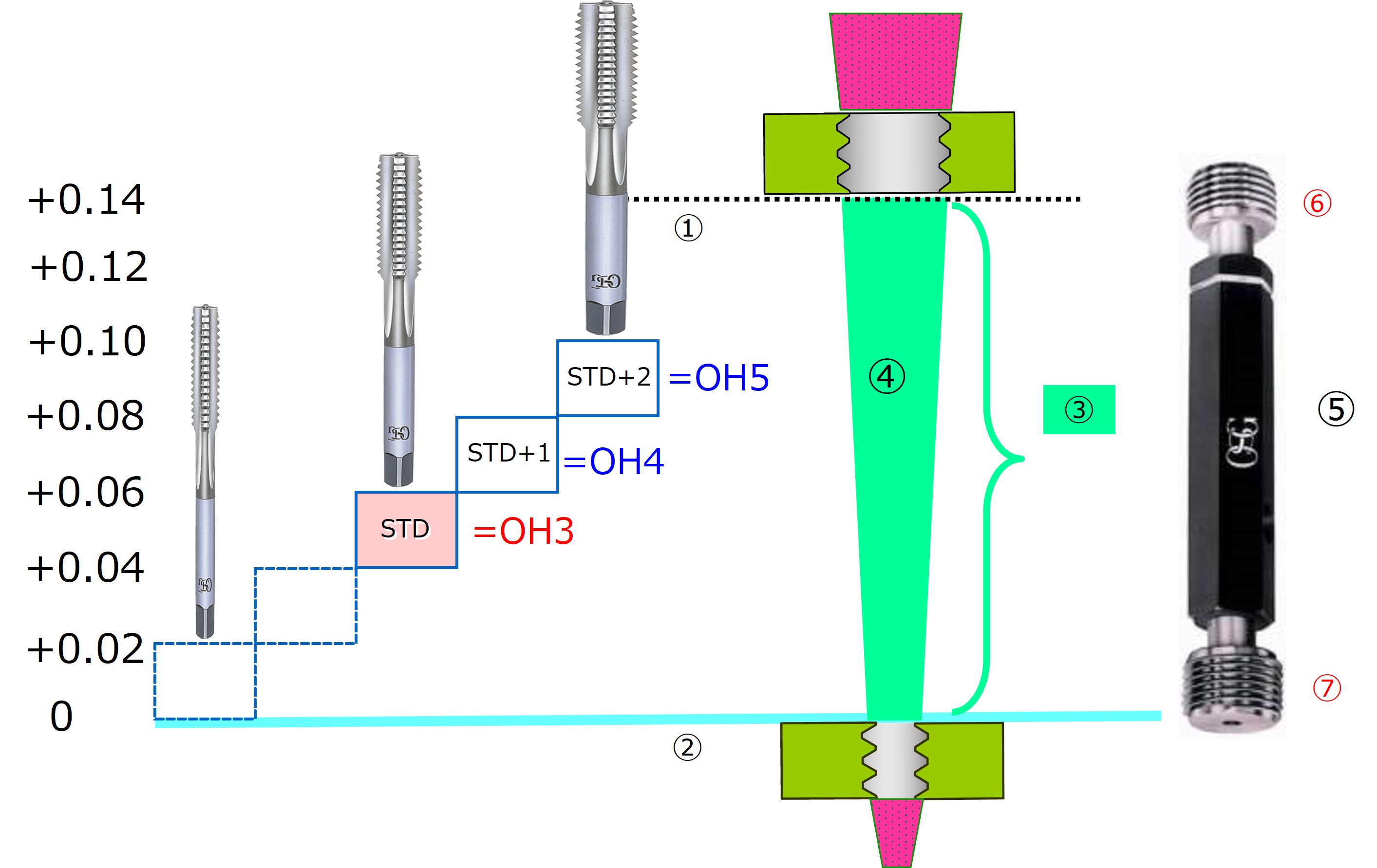

(1) Maximum diameter (2) Minimum diameter (3) Passing range (4) Grade 2 internal thread (5) Screw gauge (6) NOT-GO (Stop and pass) (7) GO (Pass through) |

・In the case of cutting taps, the amount of oversize varies depending on the pitch.

P0.6 or less is 15 μm, and P0.7 or more is 20 μm. When the STD of the tap is OH3, it is OH4 for STD+1.

The STD+1 is 0.02 mm larger in effective diameter than the STD. In STD+2, it is OH5, which is 0.04 mm larger in effective diameter than STD.

・ At forming tap , it is 12.7 μm over. In forming tap , there is no difference in the amount of oversize depending on the pitch.

Similarly, when the standard is RH7, the STD+1 is RH8, which is 0.0127 mm larger in effective diameter than the STD.

The amount of oversize required varies depending on the request, but if it is about STD+1 or STD+2,

While aiming for a thread accuracy equivalent to that of grade 2, it is possible to process large screws at the same time.

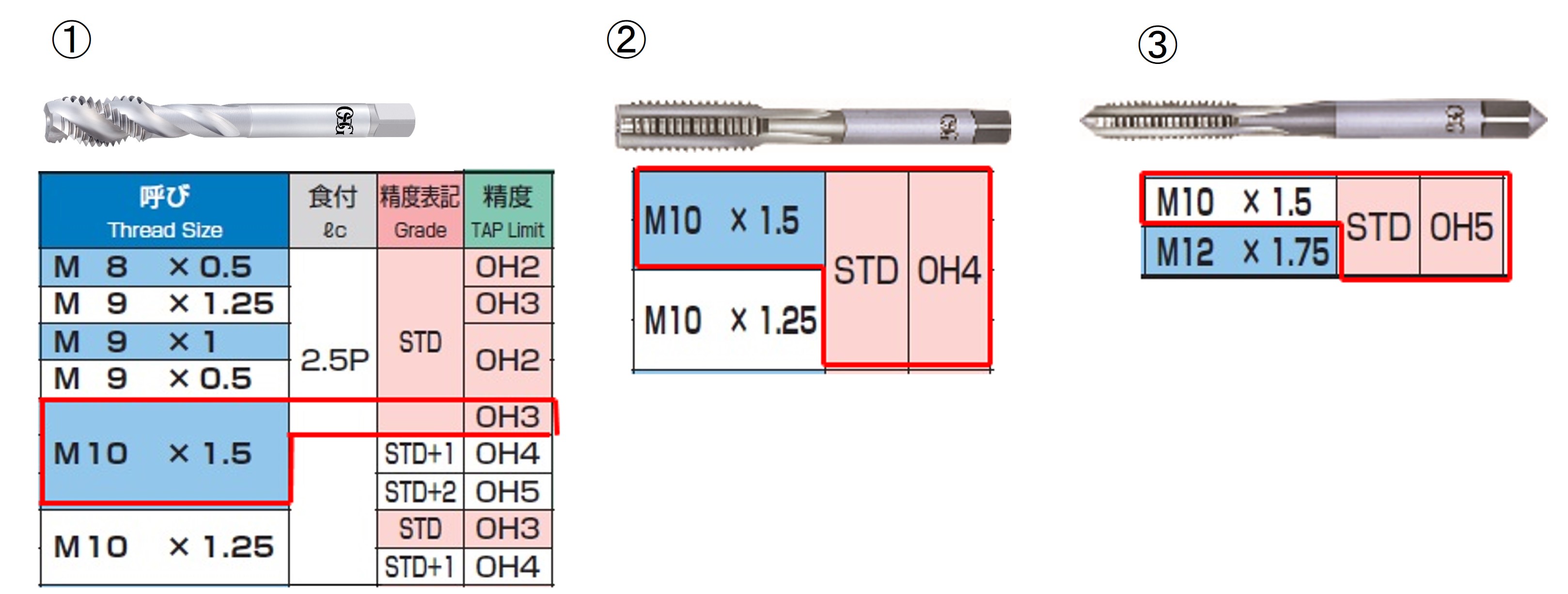

It should be noted that even with the same size (e.g. M10X1.5), the STD recommended accuracy differs depending on the application.

|

| (1) General spiral fluted tap (EX-SFT) (2) Hand tap for cast iron (EX-FC-HT) (3) Hand tap for resin (EX-PLA-HT) |