What is the part with food?

The bite part is the name of a part of the tap, and the tip is shaped like a diagonal tip.

This part bites into the workpiece and processes the screw while cutting or raising it.

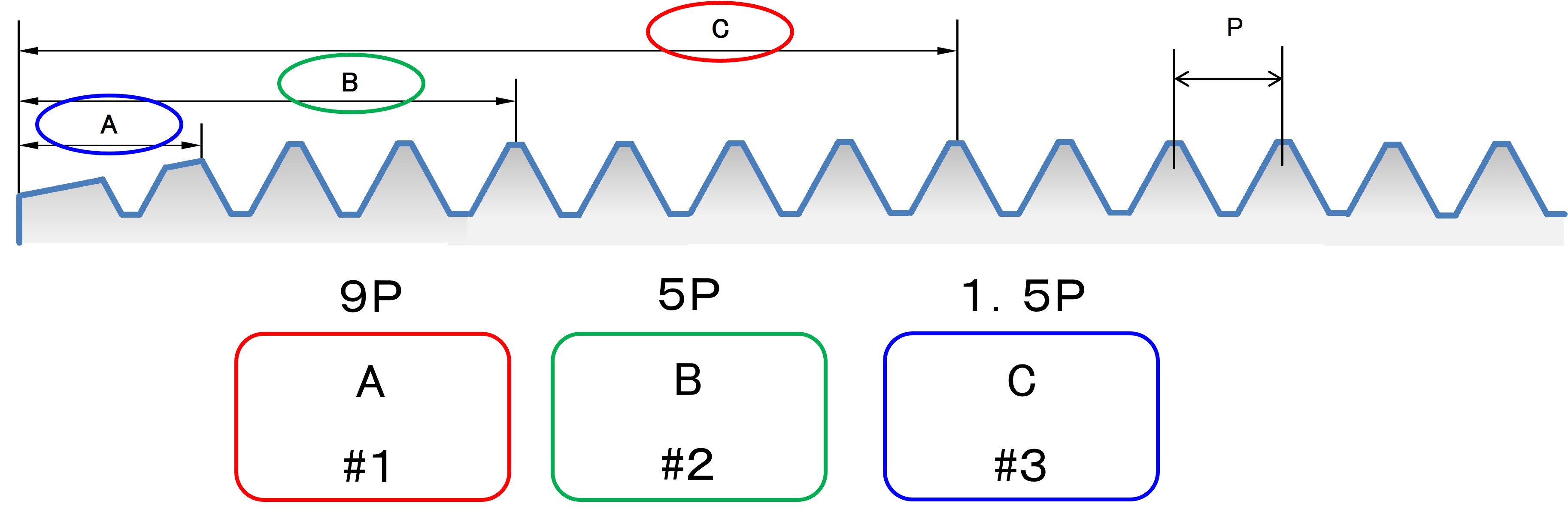

In the case of hand taps, #1, #2, and #3 are displayed on the case to indicate the length of the bite.

There is no indication of this on the actual product. The length of the part with the bite is expressed using the number of threads (pitch) of the screw. In Japan, it is also expressed as first, middle, and up.

#1: 9 Yama 9P (Ahead) "Saki"

#2: 5 Mountains 5P (Medium) "Naka"

#3: 1.5 Mountain 1.5P (Raised) "Age"

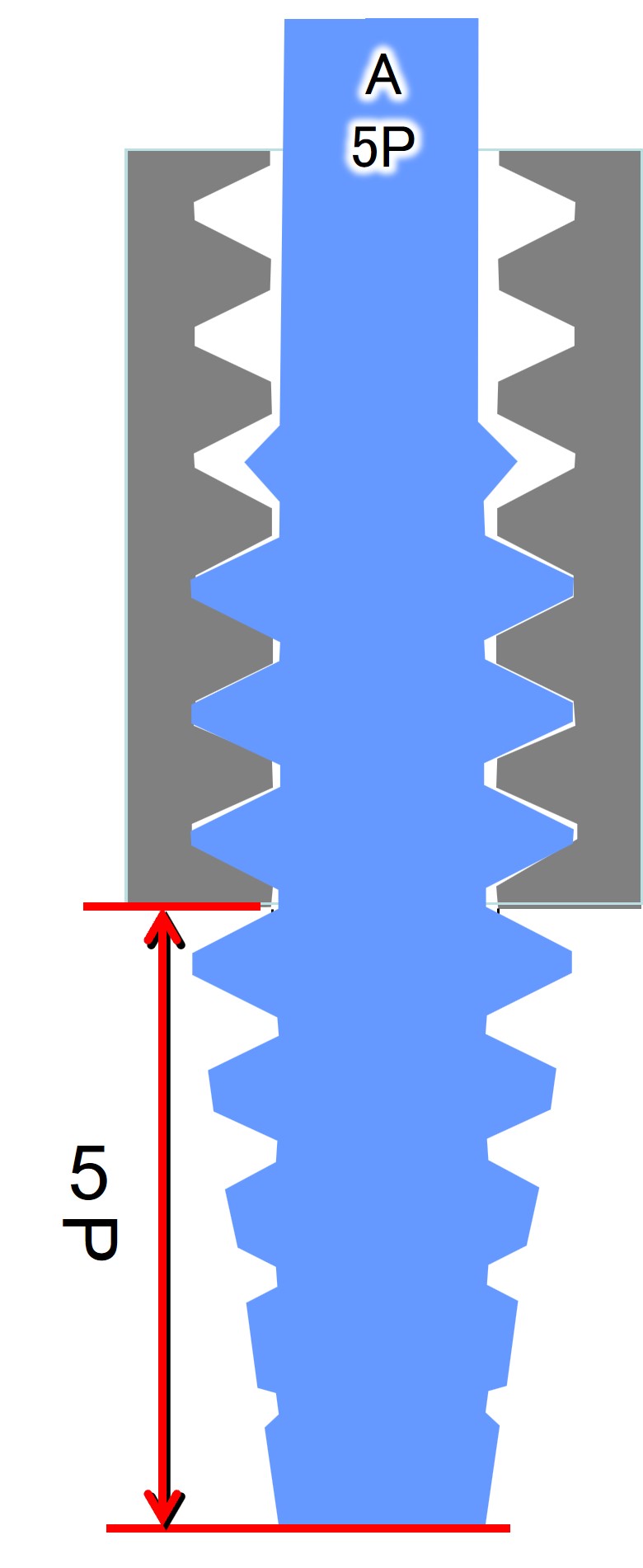

The specifications of general taps are 2.5 peaks for spiral taps and 5 peaks for point taps, but there are also other lengths for taps by type and application.

| Length with bite |

|

|

A: Ahead B: Medium C: Raised P: Pitch of screw |

・ Length of the part with the bite

The length of the bite section is required to calculate the tapping depth to ensure the effective thread length.

The pitch of the screw × calculated by the number of piles with tap feeds. Distance between metric thread pitches (mm) M10×1.5, 1.5(mm)

• Pitch of unified screws

In the call of the screw, the number of peaks between 1 inch is displayed.

The length of one mountain (pitch) is calculated by the number of ÷ 25.4 (mm)

Example: M10×1.5 Tapping of 5 mountains with bite

Length of bite = 1.5×5 = 7.5 (mm)

In particular, for holes with a limit on pilot hole depth, there is a limit to the depth at which the tap can be inserted, so it is necessary to select a tap that takes into account the length with the bite.

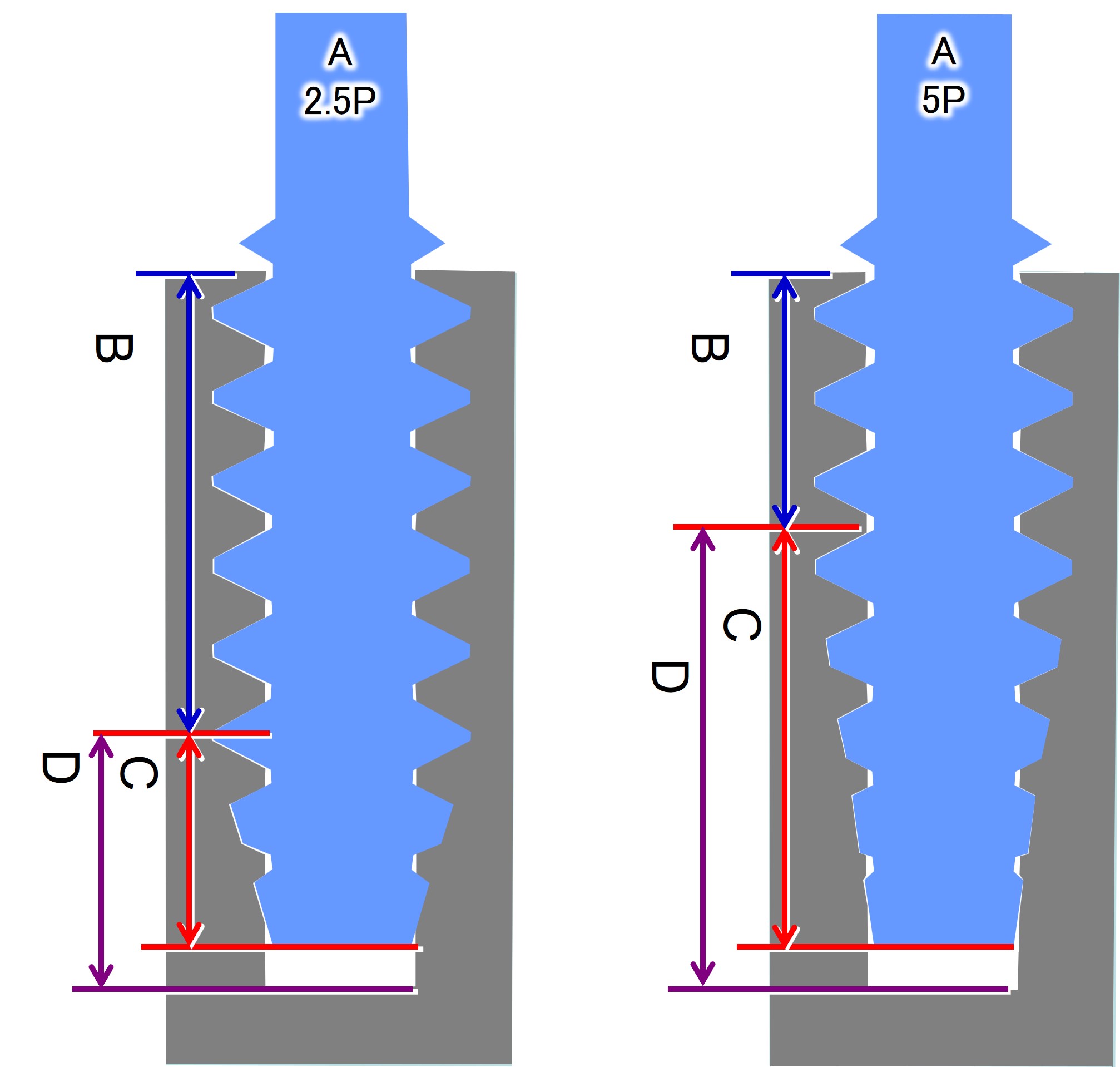

| Street Hole | Blind Hole |

|

|

|

A: With bite B: Effective thread length C: Bite length D: Incomplete thread length |

|

The bite part hits the cutting edge part of the tap, and the longer the bite part, the less the load is reduced, but the longer the incomplete threaded part.

If the bite part is short, the load will be larger, but the defective threaded part will be shorter.