Cutting data of tapered taps for pipes Calculation method PT (Rc)

The following formula is used to calculate the cutting data in the same way as for metric screws.

Rotation speed (S) = (cutting speed ×1000) ÷ Tool diameter ÷ Pi (3.14)

Feed speed (F) = pitch × rotational speed

The tool diameter is calculated using the "reference dimensions" and the pitch is calculated from the number of pils.

The reference dimensions are determined by the standard and cannot be calculated from the name like a unified thread.

Refer to the table of standard dimensions and pitches for tapered screws for pipes. (It's at the bottom of the page.) )

The reference dimensions are determined by the standard and cannot be calculated from the name like a unified thread.

Refer to the table of standard dimensions and pitches for tapered screws for pipes. (It's at the bottom of the page.) )

Calculation example: When machining a tapered tap of PT (Rc) 1/4-19 at a cutting speed of 5 m/min

ROTATION SPEED = (5X1000)÷ 13.158 ÷ 3.14 = 121.02 ... ⇒ 120 MIN-1

Feed speed = 1.3368 × 120 = 160.4... ⇒ 160mm/min

The appropriate cutting speed depends on the type of tap and the material to be cut. Please check the catalog.

When machining with a tapered tap, the machining depth is also important.

Unlike parallel screws, the deeper you put it, the larger the screw becomes.

The processing depth of the tapered tap is up to the "reference diameter position" of the tap.

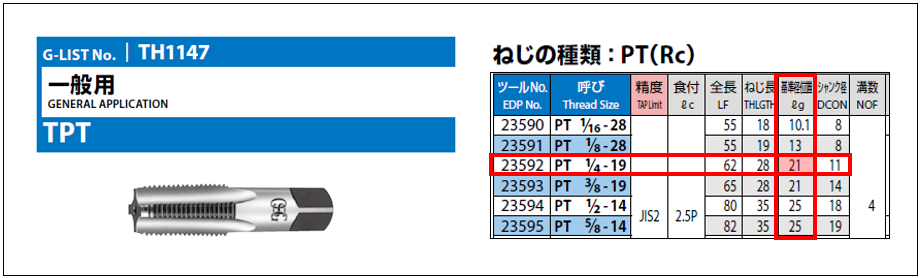

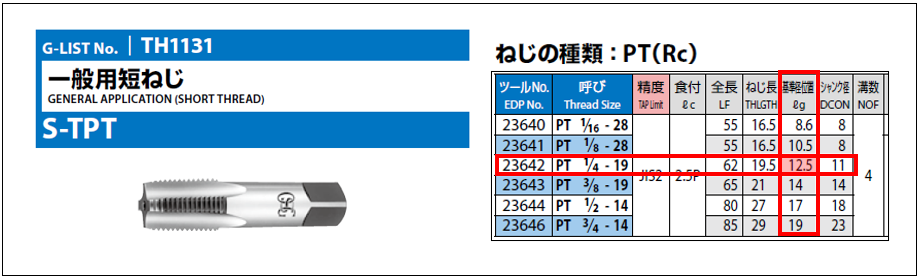

It is important to note that the size of the general use and the short thread type are different even if they are the same.

Processing depth of tapered taps for pipes PT1/4

21mm

12.5mm

Reference dimensions and pitch of pipe screws

| How to call the pipe (A) | Size (B) | Reference dimension (outer diameter) (mm) | Pitch (mm) |

| ー | 1/16-28 | 7.723 | 0.9071 |

| 6A | 1/8-28 | 9.728 | 0.9071 |

| 8A | 1/4-19 | 13.157 | 1.3368 |

| 10A | 3/8-19 | 16.662 | 1.3368 |

| 15A | 1/2-14 | 20.955 | 1.8143 |

| 20A | 3/4-14 | 26.441 | 1.8143 |

| 25A | 1-11 | 33.249 | 2.3091 |

| 32A | 1・1/4-11 | 41.91 | 2.3091 |

| 40A | 1・1/2-11 | 47.803 | 2.3091 |

| 50A | 2-11 | 59.614 | 2.3091 |

| 65A | 2・1/2-11 | 75.184 | 2.3091 |

| 80A | 3-11 | 87.884 | 2.3091 |

| 90A | 3・1/2-11 | 100.33 | 2.3091 |

| 100A | 4-11 | 113.03 | 2.3091 |

| 125A | 5-11 | 138.43 |