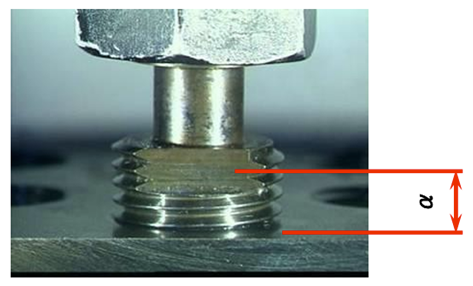

Tapered threading for pipes in a thread mill How to adjust to pass the gauge

In the internal thread processing of tapered threads for pipes with a thread mill, it is effective to adjust the tool diameter correction in order to aim for gauge passing.

・When stopping at a position shallower than the passing range of the tapered screw gauge for pipes

→Adjust the tool diameter correction value to a small size.

・When stopping at a position deeper than the passing range of the tapered screw gauge for pipes

→ Adjust the tool diameter correction value to a large extent

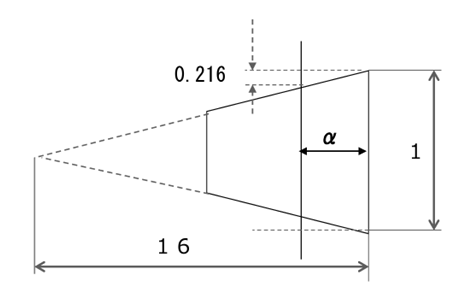

- Concept of the value to be adjusted

α=2.309×3=6.927

We recommend that you start with conservative values when making adjustments.

(FAQID:4439)