Tool selection for thread mill Pipe screws (PT, PS, Rc, Rp, R, G, PF, NPT, NPTF)

OSG's program creation tool for thread mills "ThreadPro" can be used to create everything from tool selection to programming. It greatly reduces the time and effort required to prepare the thread mill for processing.

Thread Mill Selection Procedure for Pipe Screws

(1) Check the type of screw

(2) Check the nominal and pitch of the screw.

(3) Check the thread length

(4) Check the workpiece material

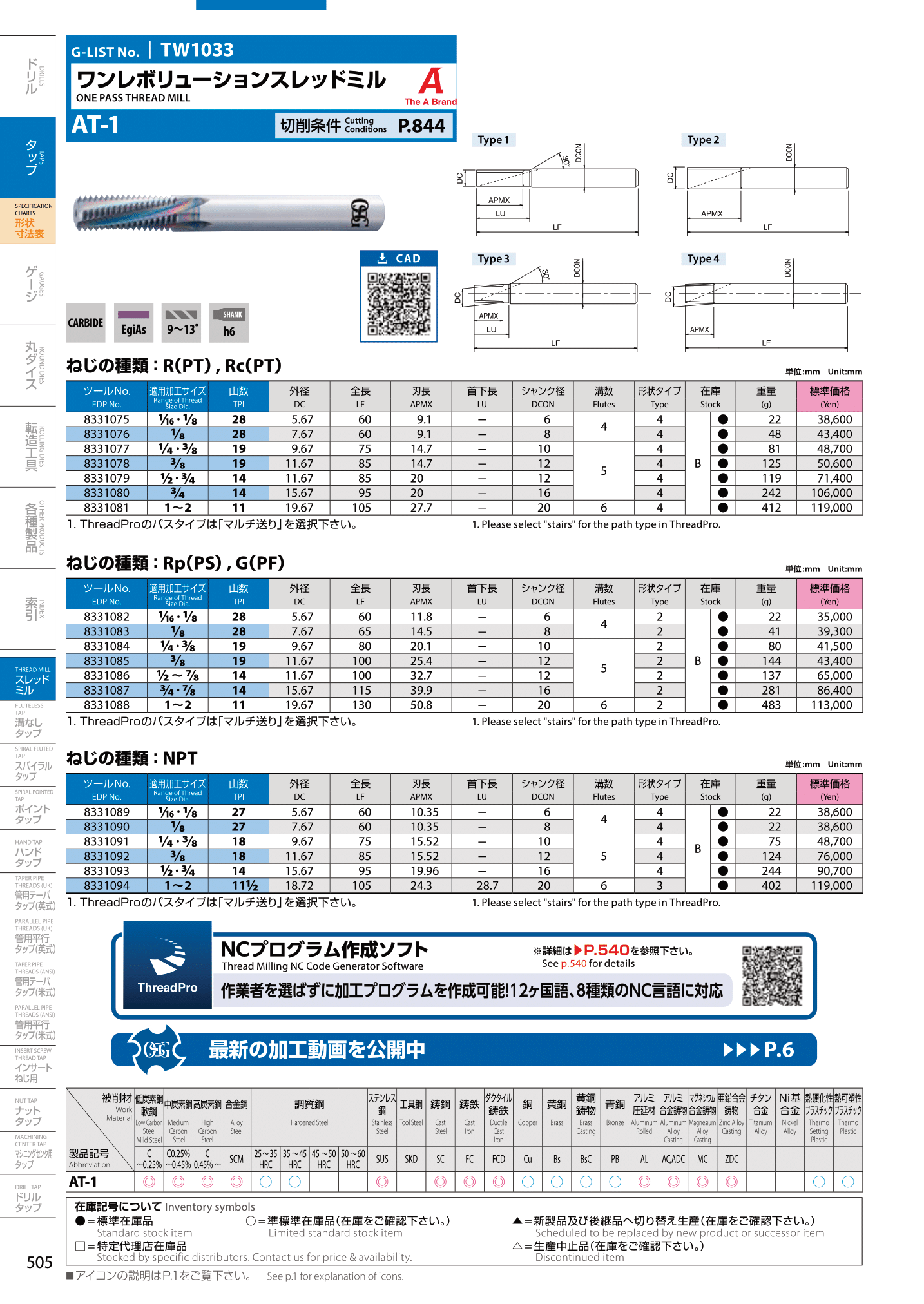

Step (1) Check the type of screw you want to process

Tapered screws for English pipes (PT, Rc, R) Male threads and internal threads can be used to share tools.

Parallel screws for English pipes (Rp, PS, G, PF) and internal threads can be used to share tools.

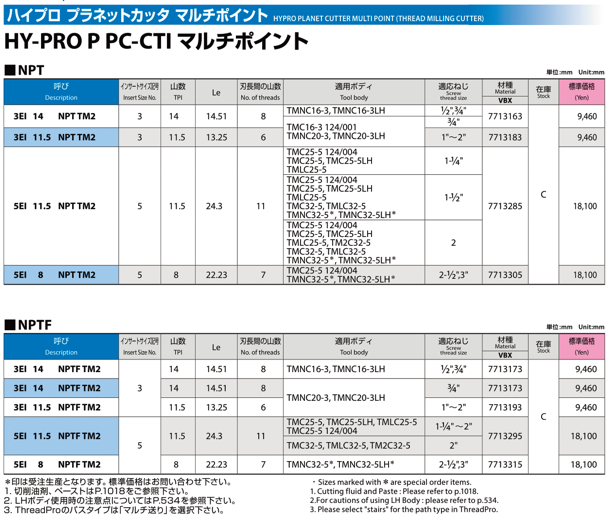

Tapered screws for U.S.-style pipes (NPT/NPTF) Tools can be shared with external and internal threads.

* Some solid types do not allow G / PF to be shared. (PNGT)

Step (2) Check the call and pitch of the screw

It can be selected from the applicable thread size. In the case of pipe screws, there are no multiple types of pitches for one thread size, such as metric threads and unified threads, but only one type.

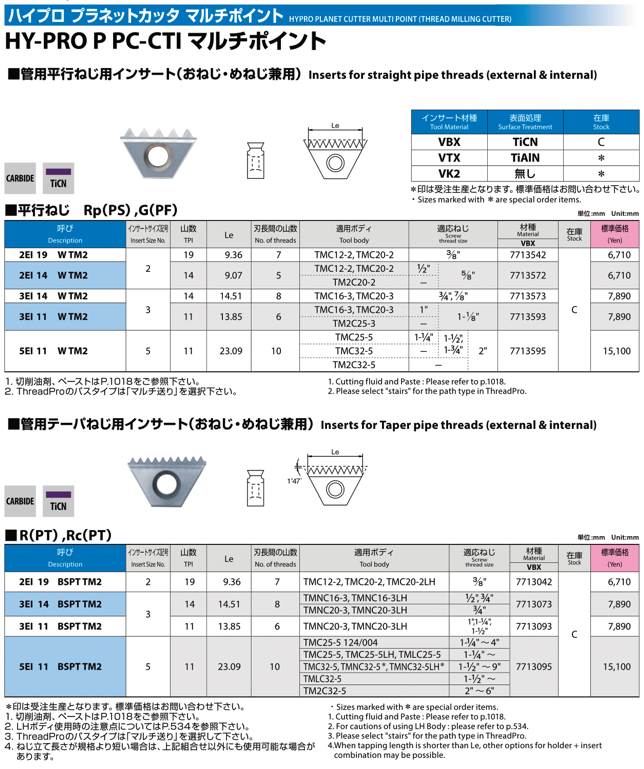

In the case of a chip type, select the holder that applies to the chip size.

* In the case of tapered screws for pipes, TMNC (for tapered screws for pipes) is basically used for chip-type holders, but depending on the combination of screw size and tool, the standard type TMC holder may be used. ThreadPro, an NC program creation tool, can introduce such combinations, so please take advantage of them.

Step (3) Check the thread length

The thread length that can be processed takes into account the margin at each thread mill, and the following is a guide.

Solid type: Blade length - 2 pitches

Tip type - Neck length - 2 pitch

Step (4) Check the workpiece material

Determine if the tool is suitable for the material you want to machine. For the solid type, there is a list of materials to be applied at the bottom of the catalog page.

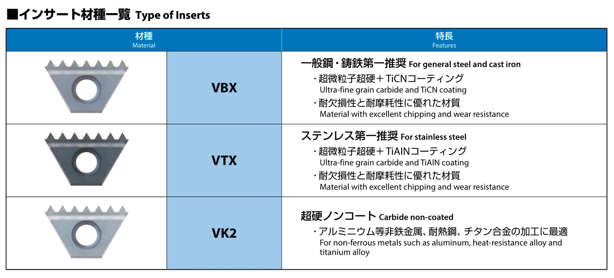

For the chip type, we recommend the general-purpose material type VBX.

The only standard stock of insert grades is the general-purpose VBX. It can handle a wide range of materials such as mild steel, carbon steel, SUS, and aluminum. We also offer made-to-order grades that specialize in specific materials.

VBX : General-purpose material grade (ultra-fine carbide + TICN coating) * Standard stock product

VTX : Stainless steel first recommendation (ultra-fine carbide + TiALN coating) * Made-to-order production

VK2 : Suitable for non-ferrous metals such as aluminum, heat-resistant steel, and titanium alloys (carbide non-coated) * Made-to-order