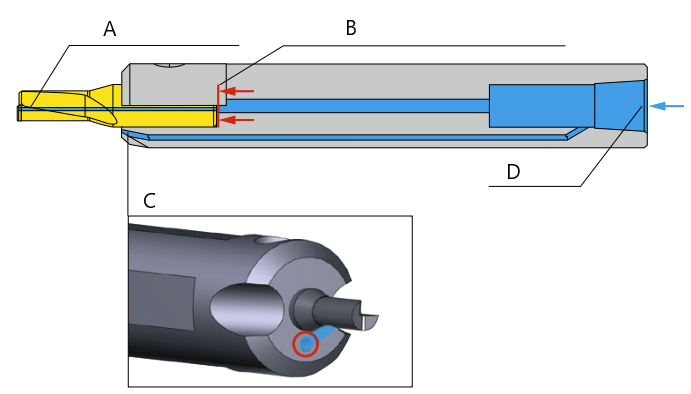

Processing is possible even without a dedicated adapter.

However, we recommend using an adapter for stable processing and repeatability of the cutting edge position.

References

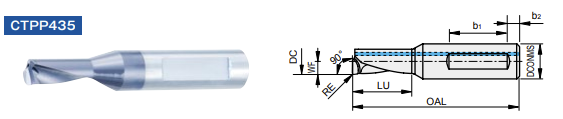

EcoCut Mini(ECM) small diameter Solid Type (Grade: CTPP435)

| Carbon Steel | P | ● |

| Stainless steel | M | ● |

| Cast iron | K | ○ |

| Non-ferrous metals | N | |

| Heat-resistant alloys | S | ● |

| High-hardness materials | H |

| DC | L/D | Tool No. | Model No. | Kitchen | DCON MS |

Overall length | Flute length | Shank section size |

RE | WF | Apply adapter type |

|

| OAL | LU | b1 | b2 | |||||||||

| 2 | 2.25D | ※ 8923137 | ECM 02L-2.25D | L | 4 | 28 | 4.5 | 11 | 3.5 | 0.1 | 1 | (1) |

| ※ 8923121 | ECM 02R-2.25D | R | ||||||||||

| 4D | ※ 8923139 | ECM 02L-4.00D | L | 31 | 8 | |||||||

| ※ 8923123 | ECM 02R-4.00D | R | ||||||||||

| 2.5 | 2.25D | ※ 8923141 | ECM 02.5L-2.25D | L | 4 | 29 | 5.63 | 11 | 3.5 | 0.1 | 1.25 | (1) |

| ※ 8923125 | ECM 02.5R-2.25D | R | ||||||||||

| 4D | ※ 8923143 | ECM 02.5L-4.00D | L | 33 | 10 | |||||||

| ※ 8923127 | ECM 02.5R-4.00D | R | ||||||||||

| 3 | 2.25D | ※ 8923145 | ECM 03L-2.25D | L | 4 | 31 | 6.75 | 11 | 3.5 | 0.1 | 1.5 | (1) |

| ※ 8923129 | ECM 03R-2.25D | R | ||||||||||

| 4.0D | ※ 8923147 | ECM 03L-4.00D | L | 35 | 12 | |||||||

| ※ 8923131 | ECM 03R-4.00D | R | ||||||||||

| 3.5 | 2.25D | ※ 8923149 | ECM 03.5L-2.25D | L | 4 | 32 | 7.88 | 11 | 3.5 | 0.1 | 1.75 | (1) |

| ※ 8923133 | ECM 03.5R-2.25D | R | ||||||||||

| 4.0D | ※ 8923151 | ECM 03.5L-4.00D | L | 37 | 14 | |||||||

| ※ 8923135 | ECM 03.5R-4.00D | R | ||||||||||

| 4 | 2.25D | 8923101 | ECM 04L-2.25D | L | 6 | 35 | 9 | 11 | 3.5 | 0.2 | 2 | (2) |

| 8923081 | ECM 04R-2.25D | R | ||||||||||

| 4.0D | 8923103 | ECM 04L-4.00D | L | 41 | 16 | |||||||

| 8923083 | ECM 04R-4.00D | R | ||||||||||

| 5 | 2.25D | 8923105 | ECM 05L-2.25D | L | 6 | 37 | 11.25 | 11 | 3.5 | 0.2 | 2.5 | (2) |

| 8923085 | ECM 05R-2.25D | R | ||||||||||

| 4.0D | 8923107 | ECM 05L-4.00D | L | 45 | 20 | |||||||

| 8923087 | ECM 05R-4.00D | R | ||||||||||

| 6 | 2.25D | 8923109 | ECM 06L-2.25D | L | 8 | 38 | 13.5 | 11 | 3.5 | 0.2 | 3 | (3) |

| 8923089 | ECM 06R-2.25D | R | ||||||||||

| 4.0D | 8923111 | ECM 06L-4.00D | L | 49 | 24 | |||||||

| 8923091 | ECM 06R-4.00D | R | ||||||||||

| 7 | 2.25D | 8923113 | ECM 07L-2.25D | L | 8 | 42 | 15.75 | 11 | 3.5 | 0.2 | 3.5 | (3) |

| 8923093 | ECM 07R-2.25D | R | ||||||||||

| 4.0D | 8923115 | ECM 07L-4.00D | L | 53 | 28 | |||||||

| 8923095 | ECM 07R-4.00D | R | ||||||||||

| 8 | 2.25D | 8923117 | ECM 08L-2.25D | L | 8 | 45 | 18 | 11 | 3.5 | 0.2 | 4 | (3) |

| 8923097 | ECM 08R-2.25D | R | ||||||||||

| 4.0D | 8923119 | ECM 08L-4.00D | L | 57 | 32 | |||||||

| 8923099 | ECM 08R-4.00D | R | ||||||||||

Note: EcoCut Mini regrinding is not available because the tool diameter and the core height of the cutting edge will change.

※=New Sizes

L = Left hand, R = Right hand

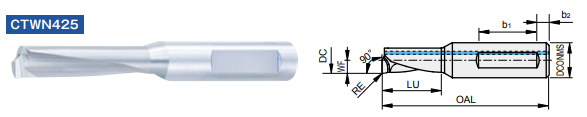

| DC | L/D | Tool No. | Model No. | Kitchen | DCON MS |

Overall length | Flute length | Shank section size |

RE | WF | Apply adapter type |

|

| OAL | LU | b1 | b2 | |||||||||

| 2 | 2.25D | 8923138 | ECM 02L-2.25D-27 | L | 4 | 28 | 4.5 | 11 | 3.5 | 0.1 | 1 | (1) |

| 8923122 | ECM 02R-2.25D-27 | R | ||||||||||

| 4.0D | 8923140 | ECM 02L-4.00D-27 | L | 31 | 8 | |||||||

| 8923124 | ECM 02R-4.00D-27 | R | ||||||||||

| 2.5 | 2.25D | 8923142 | ECM 02.5L-2.25D-27 | L | 4 | 29 | 5.63 | 11 | 3.5 | 0.1 | 1.25 | (1) |

| 8923126 | ECM 02.5R-2.25D-27 | R | ||||||||||

| 4.0D | 8923144 | ECM 02.5L-4.00D-27 | L | 33 | 10 | |||||||

| 8923128 | ECM 02.5R-4.00D-27 | R | ||||||||||

| 3 | 2.25D | 8923146 | ECM 03L-2.25D-27 | L | 4 | 31 | 6.75 | 11 | 3.5 | 0.1 | 1.5 | (1) |

| 8923130 | ECM 03R-2.25D-27 | R | ||||||||||

| 4.0D | 8923148 | ECM 03L-4.00D-27 | L | 35 | 12 | |||||||

| 8923132 | ECM 03R-4.00D-27 | R | ||||||||||

| 3.5 | 2.25D | 8923150 | ECM 03.5L-2.25D-27 | L | 4 | 32 | 7.88 | 11 | 3.5 | 0.1 | 1.75 | (1) |

| 8923134 | ECM 03.5R-2.25D-27 | R | ||||||||||

| 4.0D | 8923152 | ECM 03.5L-4.00D-27 | L | 37 | 14 | |||||||

| 8923136 | ECM 03.5R-4.00D-27 | R | ||||||||||

| 4 | 2.25D | 8923102 | ECM 04L-2.25D-27 | L | 6 | 35 | 9 | 11 | 3.5 | 0.2 | 2 | (2) |

| 8923082 | ECM 04R-2.25D-27 | R | ||||||||||

| 4.0D | 8923104 | ECM 04L-4.00D-27 | L | 41 | 16 | |||||||

| 8923084 | ECM 04R-4.00D-27 | R | ||||||||||

| 5 | 2.25D | 8923106 | ECM 05L-2.25D-27 | L | 6 | 37 | 11.25 | 11 | 3.5 | 0.2 | 2.5 | (2) |

| 8923086 | ECM 05R-2.25D-27 | R | ||||||||||

| 4.0D | 8923108 | ECM 05L-4.00D-27 | L | 45 | 20 | |||||||

| 8923088 | ECM 05R-4.00D-27 | R | ||||||||||

| 6 | 2.25D | 8923110 | ECM 06L-2.25D-27 | L | 8 | 38 | 13.5 | 11 | 3.5 | 0.2 | 3 | (3) |

| 8923090 | ECM 06R-2.25D-27 | R | ||||||||||

| 4.0D | 8923112 | ECM 06L-4.00D-27 | L | 49 | 24 | |||||||

| 8923092 | ECM 06R-4.00D-27 | R | ||||||||||

| 7 | 2.25D | 8923114 | ECM 07L-2.25D-27 | L | 8 | 42 | 15.75 | 11 | 3.5 | 0.2 | 3.5 | (3) |

| 8923094 | ECM 07R-2.25D-27 | R | ||||||||||

| 4.0D | 8923116 | ECM 07L-4.00D-27 | L | 53 | 28 | |||||||

| 8923096 | ECM 07R-4.00D-27 | R | ||||||||||

| 8 | 2.25D | 8923118 | ECM 08L-2.25D-27 | L | 8 | 45 | 18 | 11 | 3.5 | 0.2 | 4 | (3) |

| 8923098 | ECM 08R-2.25D-27 | R | ||||||||||

| 4.0D | 8923120 | ECM 08L-4.00D-27 | L | 57 | 32 | |||||||

| 8923100 | ECM 08R-4.00D-27 | R | ||||||||||

Note: EcoCut Mini regrinding is not available because it changes the tool diameter and the core height of the cutting edge.

L = Left hand, R = Right hand

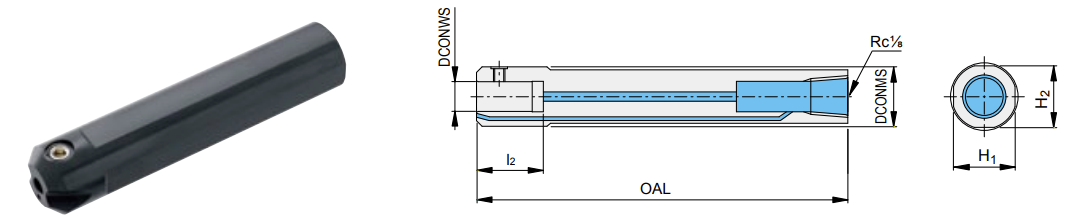

Adapter

| Adapter Type | Tool No. | Model No. | DCONWS | DCONMS | OAL | l2 | H1 & H2 | Application ECM |

| (1) | 8929017 | EC-ADJ16-04 | 4 | 16 | 100 | 18 | 15 | ECM 02... 02.5... 03... 03.5... |

| 8929018 | EC-ADJ19.05-04 | 19.05 | 120 | 18 | 17.05 | |||

| 8929019 | EC-ADJ20-04 | 20 | 120 | 18 | 18 | |||

| 8929020 | EC-ADJ22-04 | 22 | 120 | 18 | 20 | |||

| 8929021 | EC-ADJ25-04 | 25 | 120 | 18 | 23 | |||

| 8929022 | EC-ADJ25.4-04 | 25.4 | 120 | 18 | 23.4 | |||

| (2) | 8929001 | EC-ADJ16-06 | 6 | 16 | 100 | 18 | 15 | ECM 04... 05... |

| 8929002 | EC-ADJ19.05-06 | 19.05 | 120 | 18 | 17.05 | |||

| 8929003 | EC-ADJ20-06 | 20 | 120 | 18 | 18 | |||

| 8929004 | EC-ADJ22-06 | 22 | 120 | 18 | 20 | |||

| 8929005 | EC-ADJ25-06 | 25 | 120 | 18 | 23 | |||

| 8929006 | EC-ADJ25.4-06 | 25.4 | 120 | 18 | 23.4 | |||

| (3) | 8929011 | EC-ADJ16-08 | 8 | 16 | 100 | 18 | 15 | ECM 06... 07... 08... |

| 8929012 | EC-ADJ19.05-08 | 19.05 | 120 | 18 | 17.05 | |||

| 8929013 | EC-ADJ20-08 | 20 | 120 | 18 | 18 | |||

| 8929014 | EC-ADJ22-08 | 22 | 120 | 18 | 20 | |||

| 8929015 | EC-ADJ25-08 | 25 | 120 | 18 | 23 | |||

| 8929016 | EC-ADJ25.4-08 | 25.4 | 120 | 18 | 23.4 |

A wrench is supplied with the adapter.

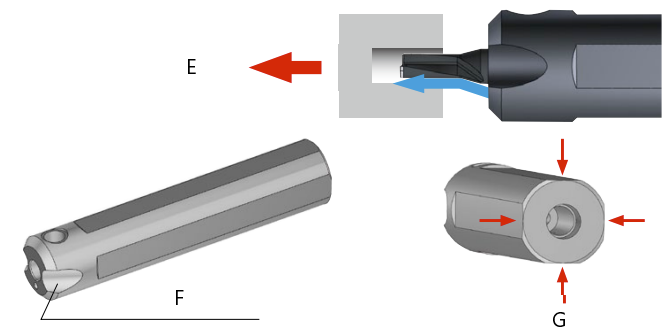

About the EcoCut Mini (ECM) Adapter

B EcoCut Mini's shank end-face restraint improves machining stability and repeatability of the cutting edge position

C In addition to the coolant that passes through the inside of the EcoCut Mini, a mechanism that injects coolant from the end face of the adapter toward the back of the EcoCut Mini.

D Internal lubrication mechanism

F Groove for access of external coolant hose

G Flattening is placed on 4 sides (90° phase)

▼ Processing data

Improvement Guidelines: Part 1

Tool consolidation and surface improvement

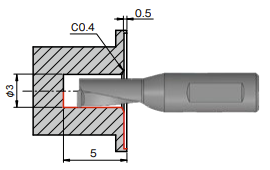

Current Processing Process

1) φ2.8 center drill

2) End-face grooving tool

3) End mills (counterboiling, end face finishing)

The end surface of the end mill is poor.

| EcoCut Mini | Another company | |

| Tool | ECM 03R-2.25D(CTPP435) | Uses 3 tools |

| Machines used | Automatic lathe | |

| Work | Spool | |

| Workpiece materials | SCM420 | |

| Drilling | End face turning | |

| Cutting speed Vc (m/min) |

30 | 15 |

| Feed amount f (mm/rev) |

0.03 | 0.05 |

| Infeed AP (mm) |

φ3 | 0.5 |

Result

・EcoCut Mini for tool consolidation

・Improved quality of the machined surface (edge surface roughness: Ra 1.3 μm)

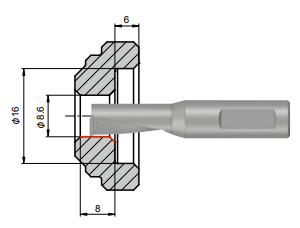

Improvement Guidelines: Part 2

Drilling holes with a current drill

Roundness cannot be obtained due to vibration during processing

Concentricity with the outer diameter of the workpiece cannot be obtained.

Inner diameter dimension tolerance (H9) cannot be obtained

Therefore, it is necessary to finish with a reamer

| EcoCut Mini | Another company | |

| Tool | ECM 07R-2.25D(CTPP435) | Uses two drills and reamers |

| Machines used | Compact NC lathe | |

| Work | Small diameter Pump Parts | |

| Workpiece materials | S25C | |

| Drilling | Internal Turning | |

| Cutting speed Vc (m/min) |

60 | 60 |

| Feed amount f (mm/rev) |

0.03 | 0.1 |

| Infeed AP (mm) |

φ7 | 0.8 |

Result

・By using EcoCut Mini for a turning finish, roundness, concentricity, and dimensional tolerances are also improved, resulting in remarless performance.

EcoCut Mini of the same size can be used with different workpieces with different dimensions, reducing tool costs.

Improvement Guidelines: Part 3

・Improvement of processing efficiency

・Reduction of tool costs

| EcoCut Mini | Another company | |

| Tool | ECM 04R-2.25D(CTPP435) | I.D. Bite |

| Machines used | Automatic lathe | |

| Work | Housing Starter | |

| Workpiece materials | SUS303 | |

| Cutting speed Vc (m/min) |

Feed amount f (mm/rev) |

Infeed AP (mm) |

| 80 | 0.05 | 0.1 |

Result

・Reduction of processing time by increasing the feed volume (f=0.03→0.05mm/rev)

・Continuous machining of 5,200 workpieces, which greatly exceeds the current 2,000 workpieces, is possible for the required accuracy of Rz 6.3 μm or less.

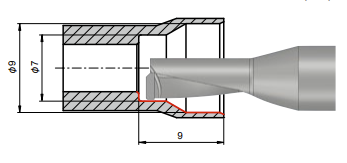

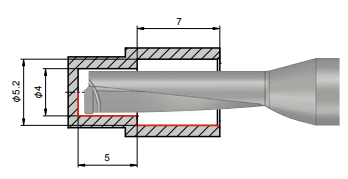

Improvement Guidelines: Part 4

Tool consolidation and machining time reduction

Current Processing Process

1) φ3.8 drill

2) φ4.0 flat drill (bottom flat finish)

3) φ5.2 part chamfering and inner diameter finishing turning

Since there is a pilot hole φ3.8, chips stretch during flat drilling.

| EcoCut Mini | Another company | |

| Tool | ECM 04R-4.00D-27(CTWN425) | Uses 3 tools |

| Machines used | Automatic lathe | |

| Work | Small bush | |

| Workpiece materials | Aluminum material | |

| Drilling | Internal Turning | |

| Cutting speed Vc (m/min) |

65 | 65 |

| Feed amount f (mm/rev) |

0.02 | 0.05 |

| Infeed AP (mm) |

φ4 | 0.12 |

Result

・Machining is possible with a single EcoCut Mini, realizing tool consolidation

・40% reduction in processing time

(FAQID:38)