For NPTF gauges for U.S.-type pipes, the central notch of the L1 gauge (three-stage notch) indicates the reference diameter, and the other two notches indicate the maximum and minimum allowable notches.

To use the gauge, screw it into the gauge until the screw stops, and if the pipe end of the screw to be inspected is within the range of the maximum and minimum notches, it is judged that the fit inspection has passed.

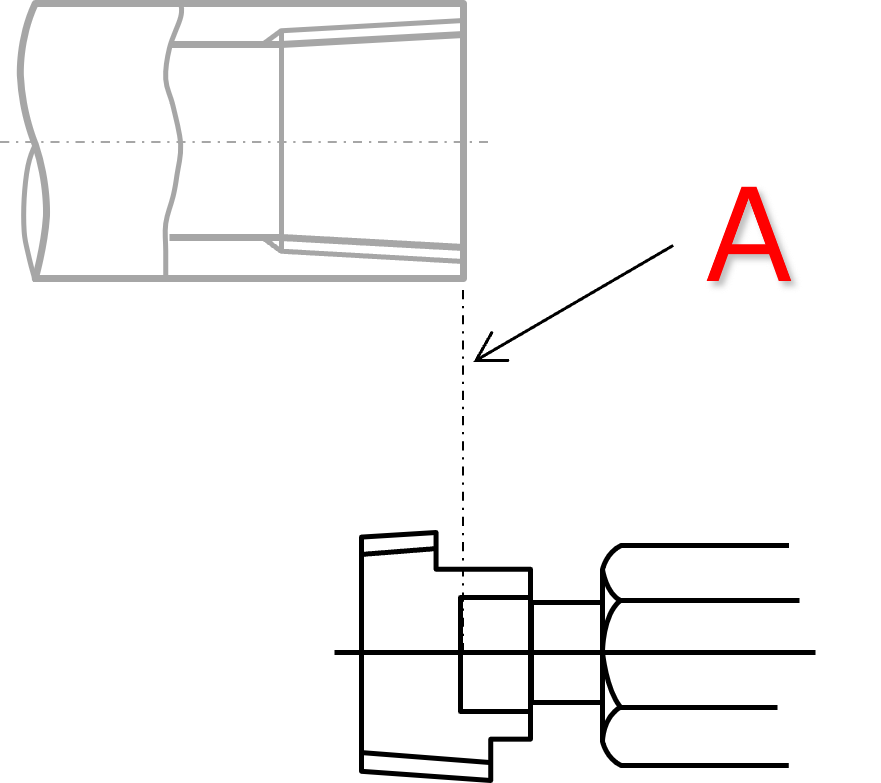

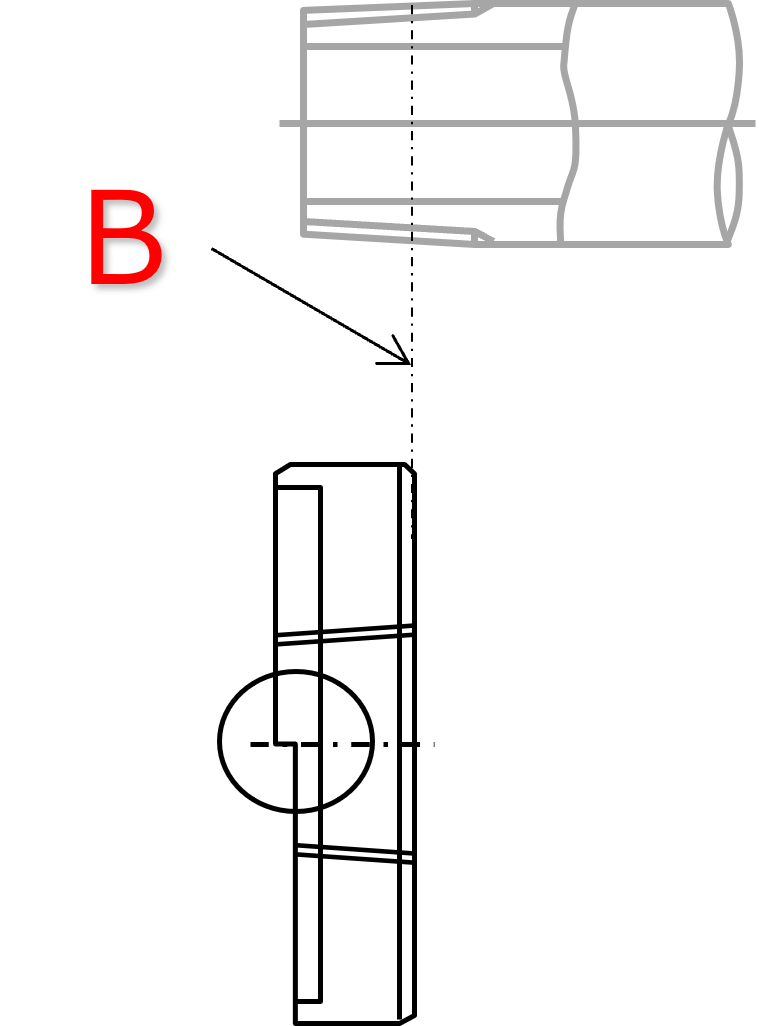

[How to use NPTF (tapered thread gauge for pipe)]

| Types of screws | Taper Nemeji | Taper external thread |

|---|---|---|

| Gauge | Tapered Threaded Plug Gauge | Tapered Thread Ring Gauge |

|

|

|

| A: Position of reference diameter | B: Position of reference diameter |

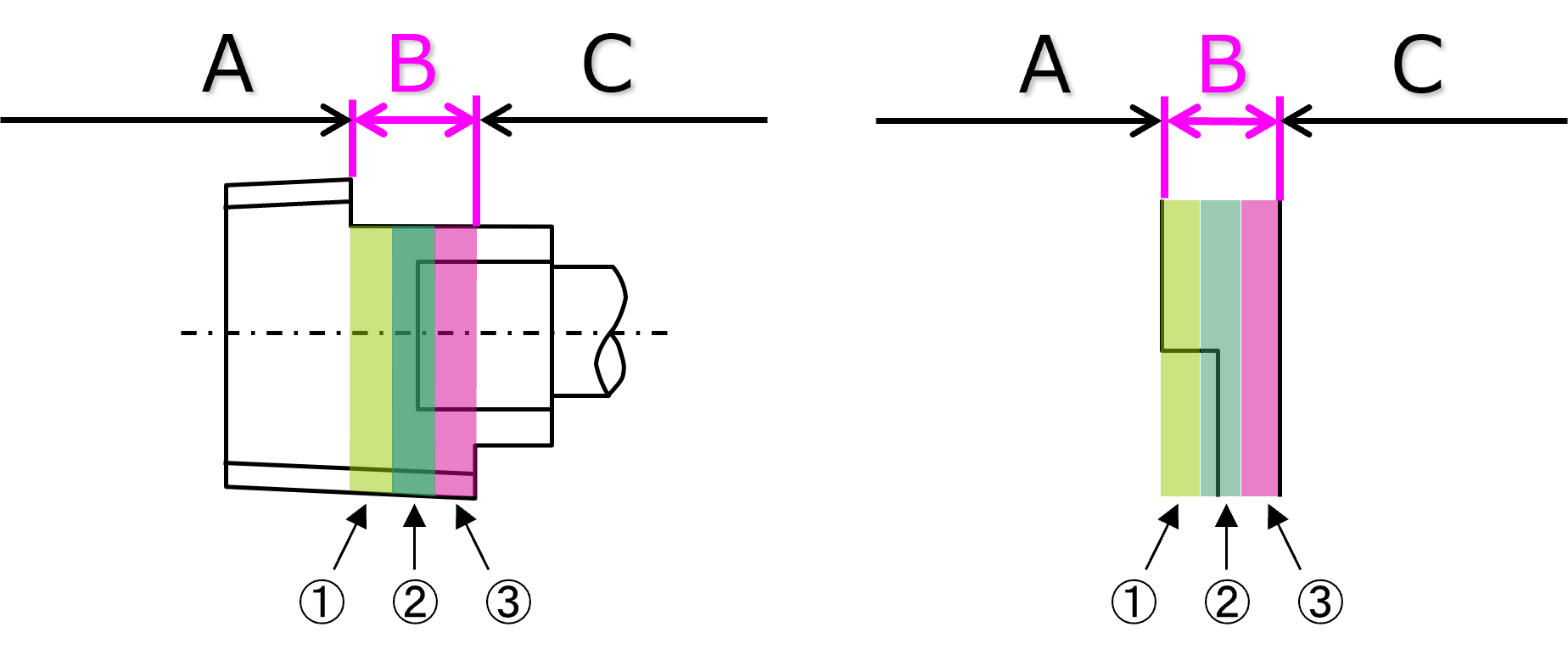

[Acceptance range of NPTF (tapered thread gauge for pipe)]

|

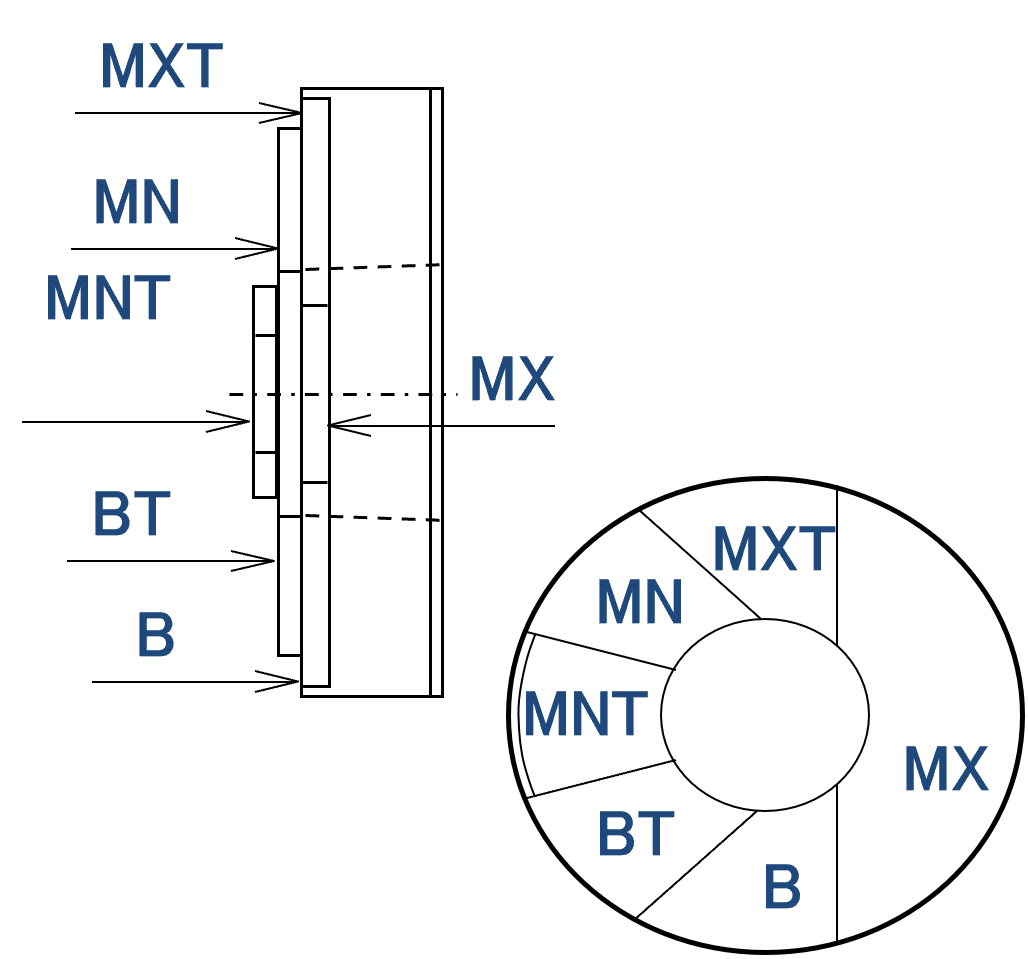

| A: Minimum notch B: Acceptance range C: Maximum notch If you pass in (1), ⇒MN~MNT If you pass in (2)⇒B~BT If you pass in (3), ⇒MX~MXT |

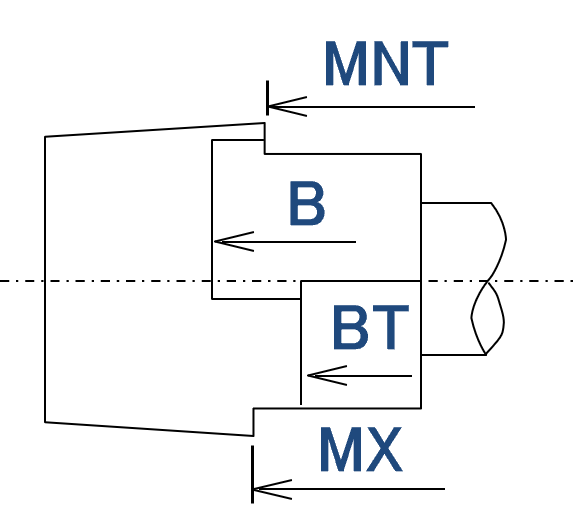

[Check the height of the thread]

| For minor diameter Tapered Plane Plug Gauge CREST CHECK |

For outer diameter Tapered Plain Ring Gauge CREST CHECK |

|---|---|

|

|

* MN and MXT are displayed on the back side.

To check the height of the NPTF threads, the L1 gauge is followed by a crest check plane gauge with a six-stage notch and the relationship between the positions where each stops.

If the position stopped at the L1 gauge and the position stopped at the crest check gauge are mutually exclusive, as shown in the range in the frame above, it will pass.

(Example: If L1 stops shallowly but the plane goes all the way in, it is NG) The official NPTF pass/fail is to include a crest check with a plane gauge, but please check it because it depends on the customer's request.

In addition, the plain gauge for crest check is a special product for both plugs and rings.