There is no uniform gauge of threads before plating.

It is important to select a gauge based on what you want to prove, not for a specific purpose.

In other words, there is no dedicated gauge for "before plating" or "for oversize Tap " as the title suggests, and the gauge to be used is decided after discussing the contents to be inspected with the customer in advance.

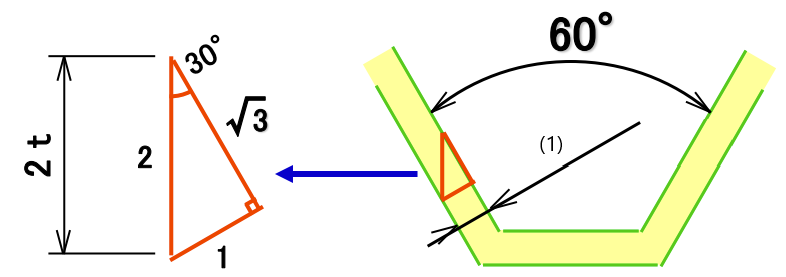

When plating is applied to internal thread , it is necessary to adjust 4 times the plating coating thickness .

▽ Chevroning and plating of screws coating thickness Approximate oversize

Trigonometric ratio⇒ 1:2:√3

Example of Screw gauge Selection

After the plating process, I want to pass the 2nd grade gauge . The plating thickness is 7 μm (0.007 mm). Since the plating process is requested externally, we want to prove that the internal thread larger than the thread accuracy grade 2 was drilled in advance in the gauge inspection before the request.

Plug used → gauge Example: "Grade 2 + 0.03"

Suitable for cases where the plating coating thickness to be processed is about 7 μm gauge

(The more effective diameter of internal thread increases: 7×4 = 28 microns ≈ + 0.03 mm)

* Please discuss the contents of the inspection with each other in advance.

Plug gauge "Class 2 + 0.03" and "6H + 0.03" are judged to be 0.03 mm "larger" in relation to the accuracy after threading. Ring gauge "Grade 2-0.03" is judged to be 0.03 mm "small" for its accuracy.

Please note that it cannot be used when the plating coating thickness is as thick as +0.1 mm. In that case, a "larger" gauge of about +0.4mm is required for plug gauge . In that case, it will be a special product.

(FAQID:232)