* What is a genuine product?

Genuine products are band saws that are attached to the machine by the manufacturer of the cutting machine.

However, many of the band saws are not in-house products, but many of them are manufactured by band saw manufacturers as OEM.

* It does not have to be a genuine product of the manufacturer.

Although it depends on each manufacturer, it seems that molybdenum-based high-speed materials are often used as the bimetal high-speed material for the cutting edge.

* What are the features (differences from genuine bands) of portable band saws handled by OSG?

The band saws handled by OSG are manufactured by WIKUS (Vickers), a global band saw manufacturer in Germany.

The bimetal of the cutting edge is made of high-grade cobalt-based high-speed M42 (SKH59 equivalent).

For this reason, the wear resistance in dry cutting is excellent, and high performance is demonstrated.

In addition, we provide customer-oriented services with an inventory system tailored to many machine manufacturers.

Reference: OSG's portable band saw

OSG-WIKUS band saws for portable machines

Achieving superior performance and high durability

Forte

• M42 cobalt high-speed material combines length tool life and sharpness

•M42 cobalt high-speed can also cut stainless steel

• Lengths are freely manufacturable

•Variable pitch is also available for intermittent cutting of pipes, etc.

We are a manufacturer specializing in replacement blades, so you don't have to choose a machine!

Please leave it to any machine manufacturer!

Length tool life Fast & Clean

Size: 1470×13×0.65-14S

Material: Round pipe outer diameter 42.7mm, wall thickness 3.5mm

Cutting Condition: Saw Speed: 53~54m Feed: Machine Gravity

Supplement: Single-cut, dry type (no oil)

| Workpiece materials | Iron | SUS304 | ||

| Another company | WIKUS | Another company | WIKUS | |

| 1st Cut(s) | 75 | 56 | 76 | 75 |

| 10th cut | 72 | 53 | 104 | 73 |

| 20th cut | 76 | 51 | 119 | 78 |

| 30th cut | 82 | 54 | 149 | 88 |

| 40th cut | 82 | 55 | 177 | 82 |

| 50th cut | 87 | 54 | 202 | 90 |

| 100th cut | 102 | 61 | 253 | 148 |

| 110th cut | 102 | 61 | 271 | 156 |

| 150th cut | 106 | 64 | 224 | |

| 190th cut | 112 | 65 | 250 | |

| 200th cut | 115 | 69 | ||

| 210th cut | 111 | 69 | ||

| 250th cut | 71 | |||

| 300th cut | 70 | |||

| 350th cut | 74 | |||

| Endurance (cut) | 217 | 353 163%UP | 119 | 196 165%UP |

| Tool life Judgment | Copper rupture | Copper rupture | Copper rupture | Copper rupture |

| Endurance | - | 1.6 times | - | 1.7 times |

| Time-saving | - | 35% reduction | - | 45% reduction |

Pitch selection

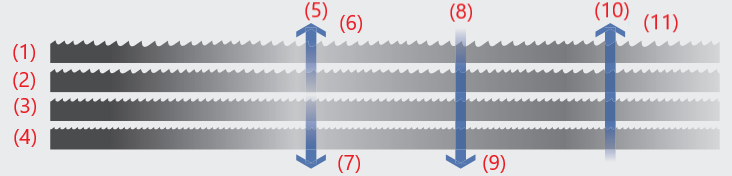

(1) 8/12S Cutting length: 15~30mm

(2)10/14S Cutting length: 5~20mm

(3)14S Cutting length: 3~15mm

(4)18S Cutting length: 1~10mm

(5) Cutting material (6) Medium meat and medium diameter (7) Thin goods and small diameter (8) Cutting surface (9) Clean (10) Cutting speed (11) Fast

| Overall length (mm) | Width (mm) | Thickness (mm) | Pitch (number of mountains) | Hitachi Koki | Shin Daiwa | Asada | Makita | Quantity | Inventory |

| 900 | 13 | 0.5 | 8/12S 10/14S 14S 18S |

CB-14/18DBL | 10 | ● | |||

| 1130 | CB-10/12※ | ● | |||||||

| 1140 | PB180D,2107F/W | ● | |||||||

| 1140 | 0.65 | RBH-120 | 736/7721 | 2106 | ● | ||||

| 1260 | CB-13 | SB-120,RB-10/120 | ● | ||||||

| 1415 | 120 | ● | |||||||

| 1425 | 125,12F | B127/128 | ● | ||||||

| 1625 | 170 | B180/181 | ● | ||||||

| 1635 | 170,185,18F | ● | |||||||

| 1640 | Beaver 6/6F | B184/185 | ● | ||||||

| 1770 | RB-18 | ● | |||||||

| 1840 | CB-18 | RB-180 | ● |

The above is an excerpt. Other sizes are also available. Check against the machine manufacturer's catalog.

● = Standard stock products

☆ Summary < questions about portable band saws>

(FAQID:149)