Drill selection procedure How to choose the right drill

Step (1) Check how many times the depth of the hole to be processed is the diameter

If the drill diameter (D) is 10 mm and the depth is 30 mm

Calculate 30÷10=3 and consider it "3D"

Step (2) Find a drill that is compatible with the workpiece material

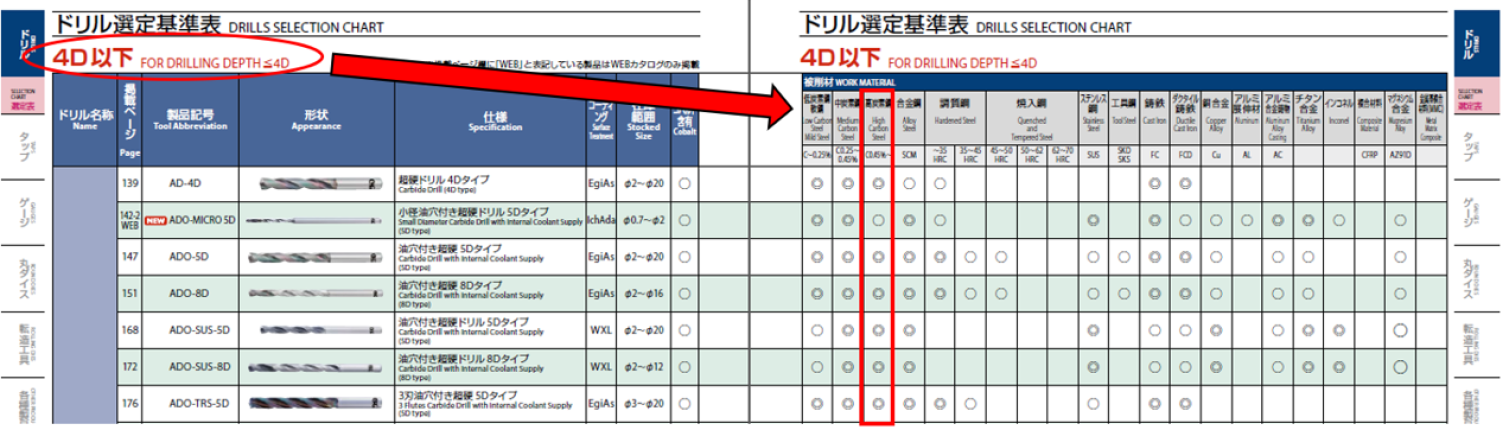

Select the drill that suits the material from the machining depth list in the drill selection criteria table of the Hole Machining Screw Machining Tool General Catalog.

[Suitability for workpiece materials] ◎: Optimal 〇: Suitable

[Suitability for workpiece materials] ◎: Optimal 〇: Suitable

Example: When selecting a drill to drill a hole with a machining depth of 4D or less

From the pages for each supported machining depth, search for the drill that is suitable for the material you want to machine.

Point

The shorter the drill, the more durable and accurate it is.

Drill flute length requires about 1.5~2D in addition to the machining depth.

The shorter the drill, the more durable and accurate it is.

Drill flute length requires about 1.5~2D in addition to the machining depth.

Step (3) Select the specifications of the drill

The type of drill is selected based on the processing equipment and the content that is emphasized.

・High-speed tool steel or carbide

・With or without oil holes

・Solid or Indexable

Step (4) Check if the desired drill diameter is in the lineup.

If you are looking for a specific drill diameter, such as Φ4.77 or Φ9.26, please use the flute length list by blade diameter.

If you are looking for a specific drill diameter, such as Φ4.77 or Φ9.26, please use the flute length list by blade diameter.

・ You can select from the OSG product search site.