Refers to a shoulder milling cutter with a cutting edge angle of 90°.

It is used when you want to use the edge of the cutting edge to cut the machined part at a right angle.

Insert shapes vary from triangle to square to rectangle, but all of them are arranged so that the peripheral flute are almost vertical.

In face milling cutters, which grind the upper surface of the workpiece, it is common to use a face mill with a cutting angle of 45° or 75° because there is little resistance in the feed direction.

However, in face mills with a cutting angle of 45° or 75°, thin-walled shapes are less rigid in the axial direction and are prone to vibration.

For this reason, a shoulder milling cutter with a cutting angle of 90°, which is less prone to cutting force in the axial direction, is effective.

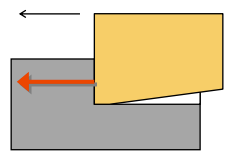

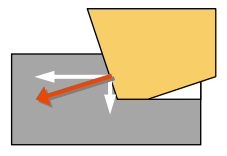

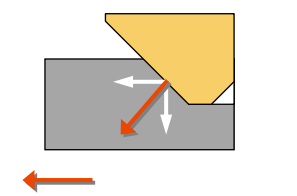

How to apply cutting load due to different cutting angles (face milling)

| Shoulder Mill 90° | Face Mill | |

| 75° | 45° | |

|

|

Direction of cutting load

|

At 90° cutters, the cutting load is applied only in the radial direction, while at 75° and 45° the force is also distributed in the axial direction, resulting in a lower radial load and higher feed settings.

→Cutters with a small cutting angle can have higher feed settings = high efficiency

Please note that when machining thin-walled workpieces with a cutter with a small cutting angle, the workpiece may become vibrated due to the axial cutting force.

Effective when using a 90° cutter with no axial force

(FAQID:10263)