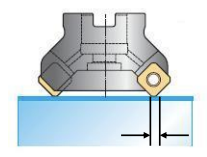

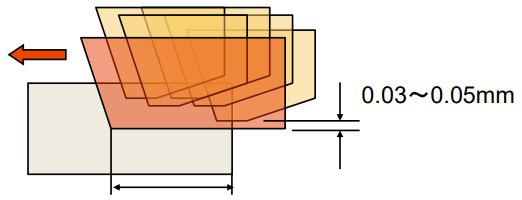

Wiper inserts have a longer secondary cutting edge than general inserts, and have a structure that protrudes slightly more than other cutting edges during installation.

Therefore, the effect of always smoothing the machined surface can be obtained, and the accuracy of the finished surface can be improved.

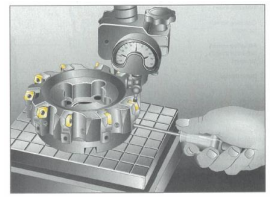

Basically, one wiper insert is set in the cutting edge of multiple general inserts.

The key is to keep the feed amount per revolution (mm/rev) within the length of the secondary cutting edge.

However, in environments where the feed amount per revolution is originally set to a large amount, such as a large-diameter cutter, multiple wiper inserts may be set and used.

Surface roughness and feed settings

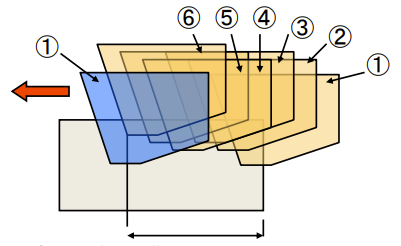

Number of flutes Image of machined surface in the case of 6 cutters

| 1. No cutting edge height adjustment | When the feed per revolution is lowered | Feed < sub-cutting edge width per revolution → The machined surface is aligned at the position of the highest cutting edge. |

|

|

|

|

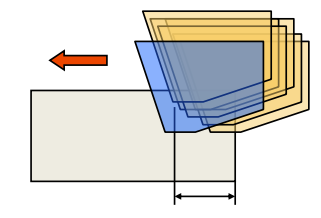

2. With cutting edge height adjustment machine |

Cutting edge adjustment required for each insert replacement | |

|

|

|

|

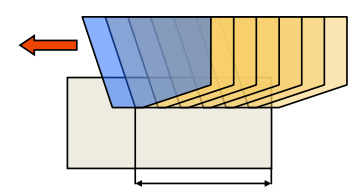

3. Adding Wiper Inserts |

||

|

Cutting edge height of wiper blades needs to be adjusted Cutter marks specific to wiper blades |

Cutters with a lineup of wiper inserts

(FAQID:10259)